Rapid Tooling Solutions

Rapid Tooling Solutions

Home » Tooling Prototype

WE USE THE BEST METHODS IN RAPID TOOLING PRODUCTION IN ASIA

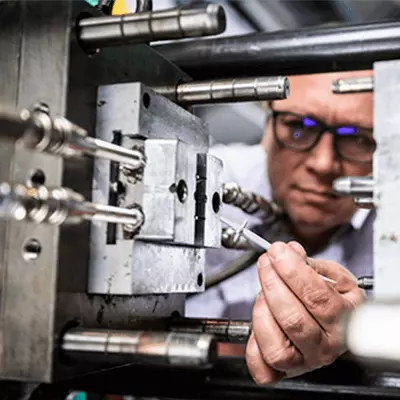

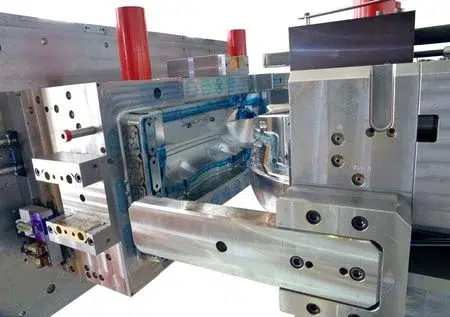

As experienced providers for the industry, we offer custom tooling services that include fixtures, jigs, cutting tools and patterns, assembly jigs, gauges, moulds, and dies, to mention a few. These rapid manufacturing tools evaluate every detail before production to detect problems during our Design for Manufacturability (DFM) analysis.

Our tooling process adapts to your needs and requirements, offering outstanding capability, technology, and engineering knowledge to accomplish any goal, as challenging as it may seem.

HIGHEST QUALITY

Accurate, five-star prototypes and production tools

COMPETITIVENESS

Reasonable costs thanks to our worldwide facilities

KNOW-HOW

Projects lead by skilled and experienced engineering teams

PROTOTYPING | PRODUCTION | LOW VOLUME | EXPORTATION

TIME-SAVING & COST-EFFECTIVE

TOOLING MANAGEMENT

- DFM (Design for Manufacturability) analysis

- Project & Quality

- Management

- Progress Reports

- Inspection, Modification, Maintenance

- Tool Trials

- Mould Flow Analysis

TOOLING RELIABILITY

EXPERIENCE

Our Rapid Tooling Package Solutions

From initial design to tooling and testing, ARRK Asia delivers trustworthy, efficient results using various rapid tooling methods.

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

BLOGS & NEWS

How Safe Are EVs? The Engineering Behind Safer Vehicles

As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

How to Solve Sheet Metal Fabrication Challenges?

Sheet metal fabrication plays an important role in industries such as automotive, electronics, EV infrastructure, and industrial equipment. Techniques like stamping aluminium, sheet bending, and metal pressing enable the production of a wide range of parts. However, these processes also present challenges that can affect precision, lead times, and costs.

WHAT DOES DIGITALISATION MEAN FOR MODERN MANUFACTURING?

Manufacturing today faces growing pressure for efficiency, flexibility, and quality. Digitalisation offers a powerful solution to optimise production, minimise downtime, and enhance supply chain visibility without significant increases in cost or workforce.

HOW DOES DIGITALISATION ENHANCE PRODUCT DEVELOPMENT TODAY?

In today’s fast-moving market, product development teams face the challenge of innovating quickly while maintaining quality and controlling costs. How can your business speed up development and achieve better results? The answer is digitalisation.

TESTIMONIALS

Applications of Rapid Tooling Across Industries

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation

Begin Your Rapid Tooling Journey With Us Today

Rapid Tooling Frequently Asked Questions (FAQs)

Rapid tooling is a manufacturing process that quickly and cost-effectively creates moulds or tools, typically for prototyping or low-volume production.

The rapid tooling process involves designing and manufacturing tools using rapid manufacturing techniques. These tools are then used to produce functional prototypes.

Unlike traditional rapid tooling which involves creating a pattern first and then using that pattern to make the tool through secondary processes, direct rapid tooling is an approach where the final mould, die, or tool used for producing parts is created directly using rapid prototyping.

The common rapid tooling materials are steel and aluminium. At ARRK Asia, we customise our rapid tooling solutions based on your material needs. We will recommend the best material for your prototype.

Rapid tooling offers various benefits, such as low production costs and quick design production. Rapid tooling helps businesses to produce their products quickly and penetrate the market more efficiently.

ARRK Asia provides professional rapid tooling solutions to help produce reliable prototypes based on your needs and requirements. We streamline your product development processes and help businesses to penetrate the market quickly.

ARRK Asia provides rapid tooling throughout Asia, delivering our expertise in product development and low-volume production throughout Malaysia, Singapore, Thailand and more. Contact us to find out more!

Our Company in Asia

PENANG,

MALAYSIA

Sales Office

Ideal Avenue 1-3-12,

Medan Kampung Relau 1,

11900 Bayan Lepas, Penang, Malaysia

Tel: +604 638 1227

Pathum Thani,

THAILAND

Sales and Manufacturing

147 Bangkadi Industrial Park,

Bangkadi, Pathumthani

Pathum Thani 12000, Thailand

Tel: +66 2501 1170

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052

Kuala Lumpur,

MALAYSIA

Sales Office

Block E-10-01, Oasis Ara Damansara,

Jalan PJU 1A/7A, Ara Damansara,

47301 Petaling Jaya, Selangor, Malaysia

Tel: +603 7734 7692

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052