Explore Our Professional Rapid Prototyping Solutions

We offer a wide range of prototyping development services to provide you with realistic representations of your final product.

Leverage our industrial 3D printing services to create highly customisable prototype design.

We provide advanced 5-Axis CNC machining service for producing low-volume parts with exceptional precision.

Complete your prototype within time and budget constraints while preventing future pitfalls by evaluating vacuum casted parts before production.

Our prototyping development services utilise cutting-edge microwave moulding technology to create prototypes using actual production materials.

RAPID PROTOTYPING

Our streamlined services and technological expertise ensure that you will receive high-quality rapid prototype models with regard to aesthetics and functionality.

Design model

Give your vision life with design models suitable for presenting to all stakeholders or conducting market research. We offer a wide range of services, including prototyping materials, selecting surface finish, integrating lights into prototype models, and everything else an industrial design model needs to be the perfect partner to achieve your goals.

Design model

Give your vision life with design models suitable for presenting to all stakeholders or conducting market research. We offer a wide range of services, including prototyping materials, selecting surface finish, integrating lights into prototype models, and everything else an industrial design model needs to be the perfect partner to achieve your goals.

3d printing

Leverage our 3D printing services such as Stereolithography (SLA) and Selective Laser Sintering (SLS) for rapid prototyping. We create high-quality prototypes and production parts with fast turnaround times to accelerate your development cycles.

cnc machining

Our advanced 5-Axis machining produces low-volume machining parts with exceptional precision. We can produce parts of various complexities and sizes, meeting your needs for prototyping and production.

Microwave molding

Utilize cutting-edge microwave molding technology to create prototypes using actual production materials. This unique approach allows for more accurate product testing.

GAIN GREATER CONTROL OVER YOUR PROJECTS WITH A DEDICATED PROJECT MANAGER.

TOOLING

With our vast experience in production, we readily identify design issues and propose solutions, streamlining the tooling prototype development process and minimizing production lead time.

INJECTION MOLDING

Our expertise assures consistent quality and dimensional accuracy in all parts, while ensuring reasonable lead times. We offer only the best through our injection molding tooling service, enabling the high-quality and repeatable manufacturing of custom parts.

GAIN GREATER CONTROL OVER YOUR PROJECTS WITH A DEDICATED PROJECT MANAGER.

Our team of experts including designers and engineers work on the necessary tools to manufacture parts, prioritising sharpness and precision.

Our expertise assures consistent quality and dimensional accuracy, enabling the high-quality and repeatable manufacturing of custom parts.

We leverage on our expertise to provide this highly effective method for creating precise, durable, and complex metal components

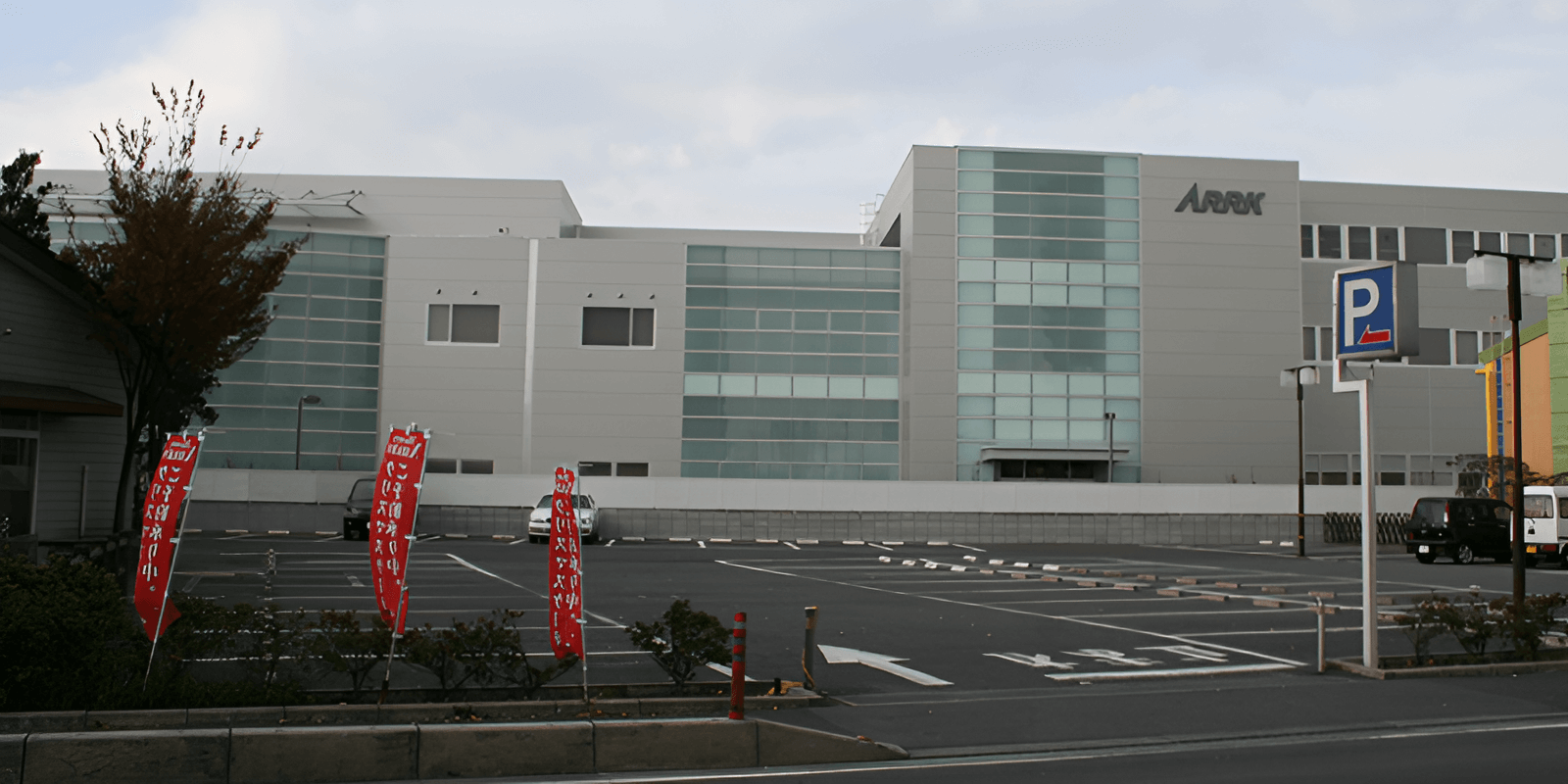

ARRK ASIA, A LEADING PROTOTYPE MANUFACTURING COMPANY

Founded in 1948 in Osaka, Japan, ARRK is a global leader in product development across various industries. With over 3,300 employees and 20+ locations worldwide, ARRK offers integrated prototyping solutions including but not limited to Rapid Prototyping, CNC Machining, Injection Moulding, Die Casting, Vacuum Casting, and Rapid Tooling.

Each service is backed by advanced technologies, and a team of professionals with comprehensive engineering knowledge and skills. Some of our key achievements include achieving robust development across various industries such as aerospace, medical, automotive and electronics.

EXPERIENCE

HIGH-QUALITY PRODUCT DEVELOPMENT SERVICES & PACKAGE SOLUTIONS

GUIDING YOU EVERY STEP OF THE WAY

EXPAND YOUR DESIGN RESOURCES

MASTERY IN EVERY PRODUCT DEVELOPMENT PROCESS

Our value

Design centric

Highly skilled engineers & craftsmen

PACKAGE SOLUTIONS

PACKAGE SOLUTIONS

Design centric

Highly skilled engineers & craftsmen

CASE STUDIES

BLOGS & NEWS

How Safe Are EVs? The Engineering Behind Safer Vehicles

As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

How to Solve Sheet Metal Fabrication Challenges?

Sheet metal fabrication plays an important role in industries such as automotive, electronics, EV infrastructure, and industrial equipment. Techniques like stamping aluminium, sheet bending, and metal pressing enable the production of a wide range of parts. However, these processes also present challenges that can affect precision, lead times, and costs.

WHAT DOES DIGITALISATION MEAN FOR MODERN MANUFACTURING?

Manufacturing today faces growing pressure for efficiency, flexibility, and quality. Digitalisation offers a powerful solution to optimise production, minimise downtime, and enhance supply chain visibility without significant increases in cost or workforce.

HOW DOES DIGITALISATION ENHANCE PRODUCT DEVELOPMENT TODAY?

In today’s fast-moving market, product development teams face the challenge of innovating quickly while maintaining quality and controlling costs. How can your business speed up development and achieve better results? The answer is digitalisation.

TESTIMONIALS

WE PROVIDE PROFESSIONAL PROTOTYPING SERVICES ACROSS VARIOUS INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation