Vacuum Casting

Easily reproduce your design with vacuum casting process by using a 3D printed or machined master to create silicone rubber moulds. This is a cost-effective solution with consistent prototypes, be it in small quantities or in the region of hundreds.

Vacuum Casting

Easily reproduce your design with vacuum casting process by using a 3D printed or machined master to create silicone rubber moulds. This is a cost-effective solution with consistent prototypes, be it in small quantities or in the region of hundreds.

Home » Cast Urethane Parts

YOUR TRUSTED PARTNER FOR VACUUM CASTING PROTOTYPES IN ASIA

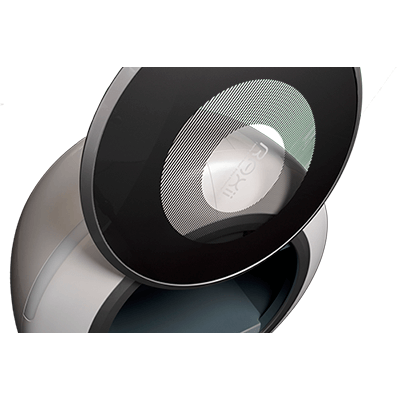

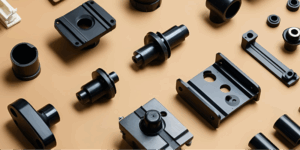

With our expertise, we provide vacuum casting prototyping services that produce high quality, low volume parts resembling final production in shape, size, appearance, and finish. We provide parts in various plastics and soft urethane materials, with a wide range of colours and textures which ARRK will pigment match according to selected Pantone, NCS, RAL colour codes or even based on physical colour samples.

More Choices

Wide range of resins, size, finishing options

High Quality

Accurate and high quality cast copies with an immaculate finish

Speed to Market

Quick turnaround for a reduced time to market

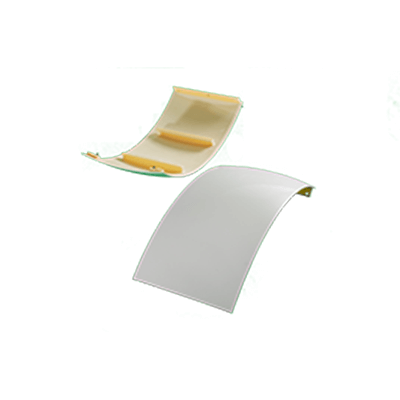

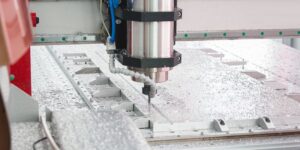

Vacuum casting process

STAGE 1. Master model

STAGE 2. Silicone mold

STAGE 3. Casting chambers

STAGE 4. Urethane part

STAGE 1. Master model

STAGE 2. Silicone mold

STAGE 3. Casting chambers

STAGE 4. Urethane part

CREATING CUSTOM MANUFACTURED VACUUM CASTINGS

ARRK implements stringent quality checks throughout our manufacturing processes to ensure that the vacuum casting parts are always of the highest quality attainable. We are always there to guide you on the best possible ways to realise your product design.

VACUUM CASTING

RIGID VACUUM CASTING MATERIALS

To view Data Sheets for our Rigid Vacuum Casting Materials, please click the links below.

ELASTOMERIC VACUUM CASTING MATERIALS

We produce elastomeric vacuum castings ranging from 20 Shore A to 90 Shore A. The materials can be used for everything from keypads, buttons, to O-rings.

FINISHING PROCESSES WITH MASTER CRAFTSMANSHIP AND EXPERIENCE

- Spray Painting Texture / Gloss

- Logo and Graphics Application

- Electroforming Plate

- Gold Color

- Spin Line

- Sputtering

- Vacuum Metalize

BENEFITS OF VACUUM CASTING WITH ARRK

VERSATILITY

SPEED TO MARKET

QUALITY

LOW VOLUME SOLUTION

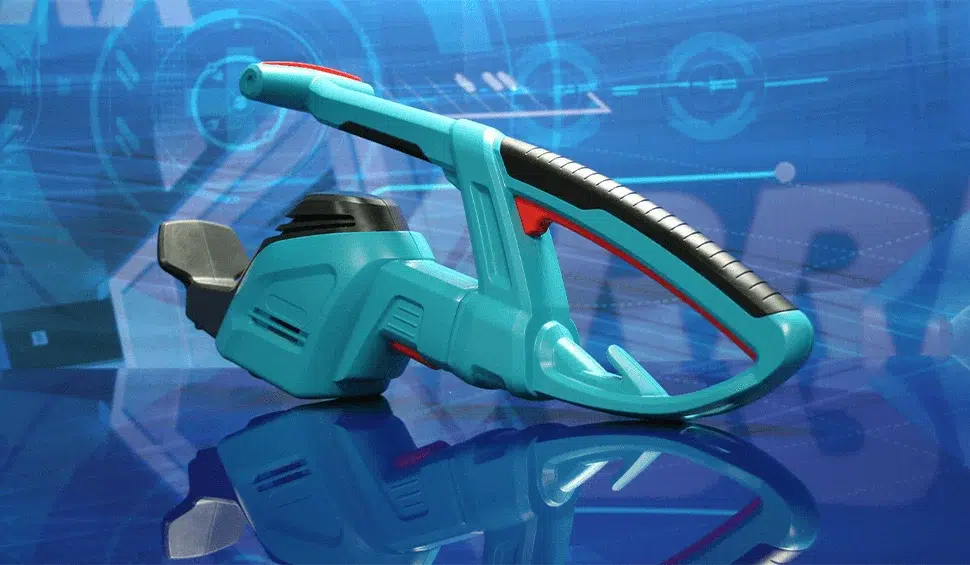

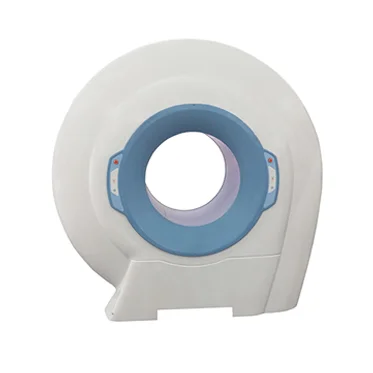

Cast vacuum parts enable various iterations of product design to be made easily so as to accommodate the rapid changes in market demands in various industries like medical, consumer goods, robotics and automotives.

The high quality of ARRK’s vacuum castings are ideal for design reviews, field testing, market research and investor presentations.

The technological advantage in ARRK’s vacuum casting services allow us to bridge a gap in production or it can serve as an interim solution. With production like quality and materials, our vacuum casted parts can even be used in some industries for low volume production run.

VERSATILITY

SPEED TO MARKET

QUALITY

LOW VOLUME SOLUTION

EXPERIENCE

Our Vacuum Casting Package Solutions

We combine your ideas with our expertise to deliver functional, high-precision prototypes. ARRK Asia provides trustworthy and flexible vacuum casting services tailored to your needs.

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

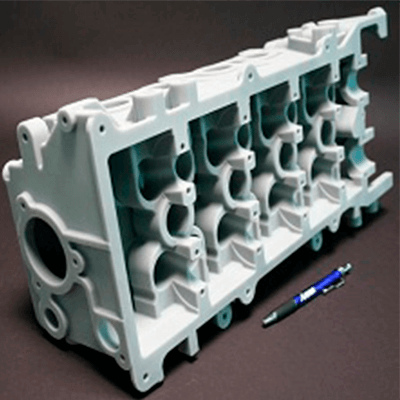

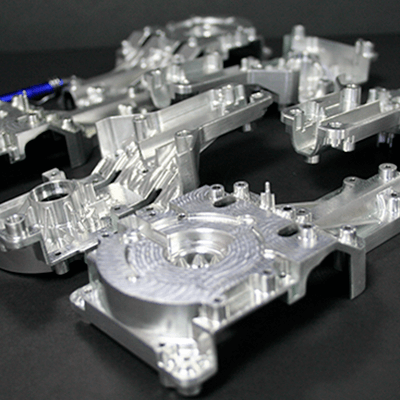

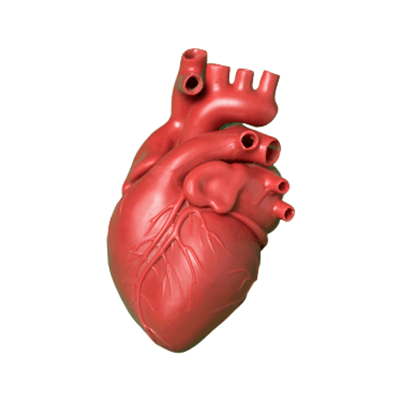

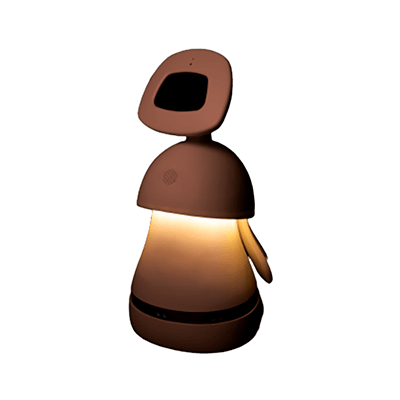

Real-World Applications of Vacuum Casting Across Industries

Browse by industry to see how detailed, durable plastic parts are made using vacuum casting. Our expertise ensures smooth finishes and functional performance for every prototype.

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

CNC Machining vs Injection Moulding: A Useful Guide

Want to learn the key differences between CNC machining and injection moulding? Read on to learn about the advantages, disadvantages, and similarities of each of the two method.

3D Printing vs Injection moulding: The Key Differences

Learn everything you need to know about 3D printing and injection moulding. In this article, we unveil the differences, similarities and the pros and cons of each method.

Understanding Overmoulding And Insert moulding

Curious about overmoulding and insert moulding? Read our article to find out everything you need to know about the two and how to choose the best option for your project!

5 Ways to Tackle Low-Volume Manufacturing Challenges

Facing challenges with low-volume manufacturing? Discover 5 smart strategies to tackle high tooling costs, streamline supply chains, and overcome customization hurdles, ensuring high-quality results in small batches.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation

Begin Your Vacuum Casting Journey With Us Today

Vacuum Casting Frequently Asked Questions (FAQs)

Vacuum casting is a manufacturing method which produces high-quality plastic parts using silicone moulds. It is commonly used for low-volume production during the initial stages of product development.

The process of vacuum casting involves using a master model to form a silicone mould. Then, the resin is injected under a vacuum. This ensures no air bubbles will form to produce precise vacuum casting plastic parts.

The most common vacuum casting materials are silicone, rubber, polyurethane and urethane. We help you choose the best materials for your vacuum casting parts.

Some of the benefits of vacuum casting include quick turnaround production times and high-quality surfaces. Businesses can produce vacuum casting plastic parts at an affordable cost.

ARRK Asia is widely known for producing vacuum casting solutions tailored to every industry. The technology and equipment used can produce precise vacuum casting plastic, rubber and silicone parts that resemble the final production part in shape, size, appearance, and finish.

ARRK Asia provides vacuum casting solution throughout Asia, delivering our expertise in product development and low-volume production in Malaysia, Singapore, Thailand and more. Contact us to know more!