As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

The good news is that behind every EV are engineers working to ensure safety without compromising performance. They achieve this through a combination of CAE simulation, advanced thermal management systems, and structural design that validate safety long before a car reaches the road.

This blog explores key areas of EV development, including battery protection, thermal analysis, and crashworthiness, and explains how engineering solutions are shaping safer, smarter vehicles.

Why EV Safety Is Different from Traditional Cars

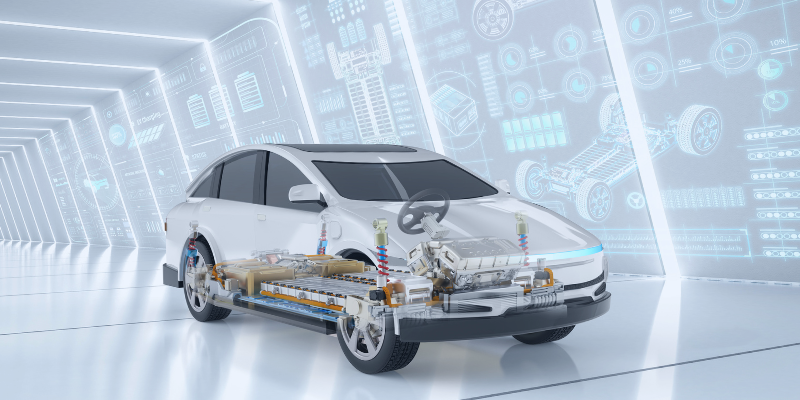

EVs are not just a swap of a traditional engine for an electric motor but require a fundamental shift in how vehicles are designed and tested.

- High Voltage Battery Systems

The high voltage battery pack is the largest and most expensive component of an EV. Protecting it during crashes is crucial for both car battery safety and occupant protection.

- Battery Thermal Management Systems

Unlike a fuel tank, batteries can overheat or suffer thermal runaway. An advanced EV battery thermal management system prevents overheating during fast charging, long drives, or extreme weather.

- Strong Structures

High-strength materials are required to improve stiffness and strength, ensuring the vehicle structure can safely accommodate the heavy floor-mounted battery pack usage and incidents over time.

These factors mean electric vehicle safety requires new methods, tools, and expertise.

Key Factors in EV Safety Design

1. Thermal Management

At the heart of every EV is a large, high-voltage battery pack that delivers the power needed for long ranges and strong performance, while requiring careful engineering to ensure safety. If battery cells overheat would risk thermal runaway, a chain reaction that can lead to system failure or fires. This requires careful engineering to ensure safety.

Key approaches:

- Refrigeration circuit

Using components such as the EXV and high voltage compressor, the refrigeration circuit conditions the battery, regulates chiller and evaporator temperatures, and ensures efficient heat pump operation.

- Coolant circuit

The coolant circuit adapts to demand by adjusting pump speeds and valve positions, while also managing heating elements for both water and air to maintain stable operation.

- Thermal simulation

CAE tools to model heat flow in the battery pack and surrounding components. This helps identify potential hotspots, validate and refine cooling strategies, and optimise the layout of cells and circuits for safety and efficiency before physical systems are built.

These measures prevent overheating, improve efficiency, extend battery life, and enhance comfort. With smart control systems and advanced simulations, ARRK helps deliver safer, more reliable vehicles while reducing costly trial and error.

2. Crashworthiness of Battery Packs

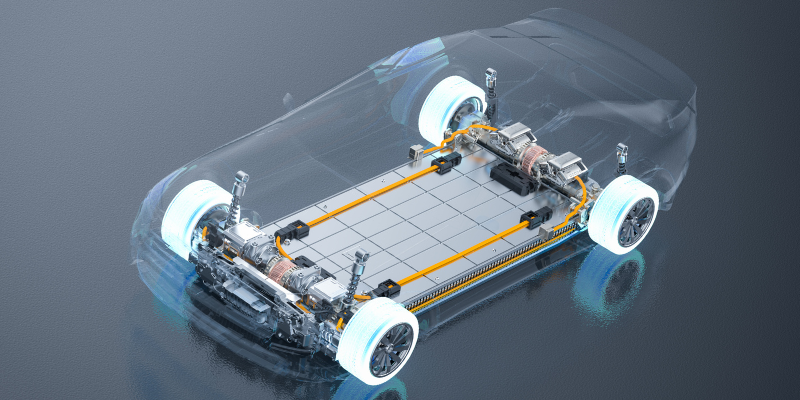

Unlike fuel tanks, EV battery packs are large, heavy, and spread across the vehicle floor which places them close to impact zones in a crash. This makes their protection a top priority, as both the battery and passengers must be kept safe.

Battery packs are not just protected by the vehicle structure—they are part of it. In some crashes, the pack can provide up to 80% of the vehicle’s stiffness, meaning its design plays a direct role in overall crash performance. The challenge is achieving the right balance: strong enough to protect, but flexible enough to avoid transferring damaging forces to the cells inside.

Key approaches:

- Crash simulations

Modelling frontal, side, rear, and rollover impacts to understand how crash forces move through the vehicle structure.

- Reinforced structures

Battery enclosures are designed to resist puncture or intrusion during severe collisions while remaining durable under static, vibration, fatigue, and crash conditions to ensure reliable performance and safety.

- Optimised load paths

Redirecting crash energy away from critical zones to protect the battery and passengers without adding unnecessary weight.

- Structural integration

Incorporating the battery pack into the overall vehicle structure to improve stiffness while maintaining enough flexibility to safeguard the cells.

At ARRK, our engineers use advanced CAE crash simulations early in the design process, combined with testing, to optimise enclosures, enhance safety, and protect the EV’s most vital component, the battery.

3. Multi-Body Simulations

Safety in electric vehicles is not only about crash performance but also how the vehicle behaves under real driving conditions. Multi Body Simulations (MBS) help engineers model the car as a system of interconnected parts such as the chassis, suspension, wheels, and drivetrain to analyse motion and forces in detail. This ensures that the weight of a high voltage battery pack does not compromise handling, stability, or passenger comfort.

Key Applications

- Vehicle dynamics and ride comfort

Studying how the EV responds to bumps, vibrations, and steering forces to deliver a stable and comfortable driving experience.

- Powertrain simulation

Analysing the interaction between the electric motor, transmission, and drivetrain to ensure smooth and efficient performance.

- Drivetrain design and load analysis

Creating reliable and efficient gear systems while predicting the stresses and forces on critical components to support long term durability.

By applying MBS together with material data, engineers can design EVs that are safe, stable, lightweight, and enjoyable to drive, while also reducing development risks and costs.

The Road Ahead for EV Safety

Safety will continue to define the success and acceptance of electric vehicles. Achieving it requires not only advanced technology but also the foresight to anticipate risks and engineer solutions before they reach the road.

ARRK applies expertise in CAE simulation, thermal management, and crash analysis to support automotive partners across various vehicle types and systems. Our engineers accelerate vehicle development to ensure the highest standards of safety and performance.

Partner with ARRK to shape safer, smarter EVs for the future. Get in touch today.