The manufacturing method and process used in product development are crucial, as they significantly impact the quality, cost, and time required for the overall product development phase. Two of the most common manufacturing methods in product development are CNC machining and injection moulding. In this article, we at ARRK Asia are here to guide you through everything you need to know about CNC machining vs. injection moulding.

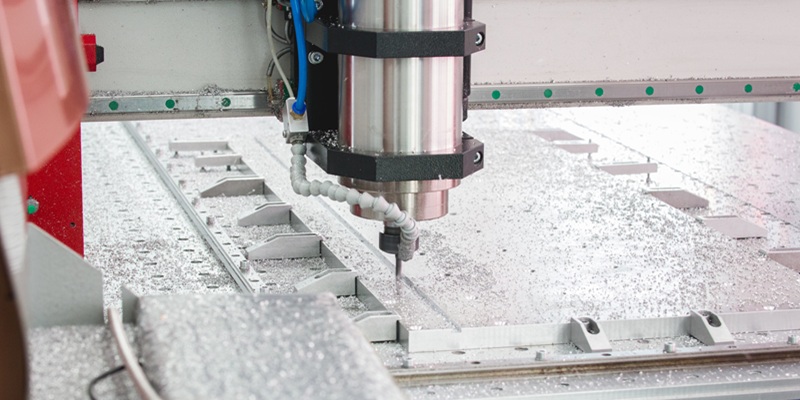

What Is CNC Machining?

CNC (Computer Numerical Control) machining is a type of subtractive manufacturing process that involves removing material from a solid block using different cutting tools.

This method is controlled by various computer programs, which adjust the movement of cutting tools according to the specific design.

Advantages Of CNC Machining

Here are some of the advantages of CNC machining and why it’s a common manufacturing method to create parts:

- Versatile materials: CNC machining can cut a wide range of materials, including plastic and metals

- Fast production: Solid material blocks are readily available to be shaped into precise parts, making the process quicker than creating complex moulds

- High-precision: Small-diameter tools can be used to craft smooth surface finishes and withstand tight tolerances

Limitations Of CNC Machining

Now, let’s take a look at the disadvantages of CNC machining:

- Expensive: It can be more expensive for highly intricate or complex geometries due to longer setup and machining times

- Longer Lead Times for Complex Parts: Highly detailed parts may require multiple setups or custom fixtures, increasing production time

- Slower Production Speed for Larger Volumes: Each part is typically machined one at a time, making it less efficient if compared to injection moulding

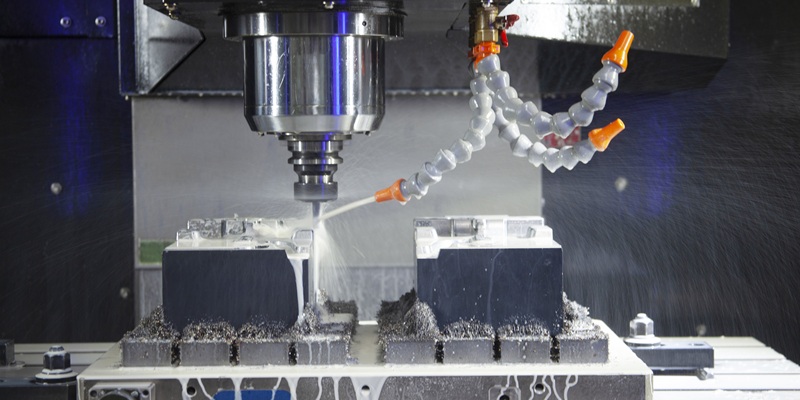

What Is Injection Moulding?

Injection Moulding is a widely used manufacturing process where molten plastic is injected into a mould cavity using an injection moulding machine (IMM). The IMM applies high pressure to ensure the liquid plastic fills every part of the mould.

As the plastic cools, it solidifies into the desired shape. Once fully hardened, the component is ejected from the mould and is ready for use.

Advantages Of Injection Moulding

As for injection moulding, here are some of the advantages:

- Fast production: Injection molding machines (IMMs) can operate without stopping, repeating the production cycle each time a part is finished and removed

- Affordable: It has the lowest price per part compared to other manufacturing methods, as the mould lasts a longer period

- Consistent Quality and Repeatability: Once the moulds are prepared, they can produce low to high volumes of precise, high-quality parts suitable for end-use applications

Limitations Of Injection Moulding

After learning about the advantages, here are the disadvantages of injection moulding:

- Design limitations: May be difficult to rework the moulds for any design changes and it can require complex moulds for different designs

- High initial investment: The tooling and equipment involve high setup costs

- Longer lead times: The fabrication of mould can take between 3 to 7 weeks depending on the complexity

CNC Machining Vs Injection Moulding: What Are The Key Differences?

Take a look at a breakdown of the key differences between CNC machining vs injection moulding below:

| CNC Machining | Injection moulding | |

| Cost | High cost per part, low upfront investment | Low cost per part, high upfront investment due to expensive tooling and mould |

| Volume | Parts are produced one by one, making it less efficient for large batches | Can produce large quantities quickly with multiple cavities |

| Speed | Fast for very small volume production | Fast for low to high volume production due to mould cavities |

| Materials | Compatible with plastics and metals | Mainly uses thermoplastics, elastomers, and thermosets |

| Accuracy, Quality & Precision | High precision, fewer imperfections, smooth surface finish | May have surface imperfections due to mould structure (two-piece mould) |

| Tolerance range | ±0.05mm to ±0.1mm | ±0.1mm to ±0.3mm reference to ISO20457 |

| Flexibility | Highly flexible, changes can be made easily by updating the CAD file | Less flexible, requires a new mould for design changes |

Let’s explore the key differences between CNC machining and injection moulding in more detail:

1. Cost

CNC machining has a high cost per part but requires a low upfront investment. In contrast, injection moulding offers a much lower cost per part, though it involves a high initial investment due to expensive tooling and moulds. However, for high-volume production, the lower per-part cost of injection moulding can offset the initial tooling expense over time.

2. Volume

Injection moulding offers significant advantages by producing low to high quantities of parts efficiently and at a lower cost per unit, utilising multi-cavity moulds to achieve rapid output in each cycle. In contrast, CNC machining is well-suited for low-volume or custom production, providing precision and flexibility without the need for dedicated tooling.

3. Speed

The speed of injection moulding is slower during the initial setup but faster after the mould is made, which can produce up to 100 parts per day. CNC machining, however, is faster in the initial set up process but is relatively slower as each part is individually milled with the cutting tool from a solid material block.

4. Materials

CNC machining supports a wide range of plastics and metals, offering versatility for both prototyping and production. Injection moulding, on the other hand, primarily uses thermoplastics, elastomers, and thermosets. These materials are often too soft or flexible to be effectively processed with CNC machining.

5. Accuracy, Quality & Precision

CNC machining offers more accuracy and precision, reducing the chance of defects during manufacturing.. This process is capable of producing parts with tight tolerances and smooth surface finishes.

In contrast, injection moulding may result in surface imperfections due to the nature of the mould, which is made from two halves joined together. While both methods can produce high-quality parts, CNC machining typically has an advantage when it comes to achieving superior surface quality and dimensional accuracy.

6. Tolerance

CNC machining generally offers tighter tolerances than injection moulding, resulting in more accurate and consistent part dimensions. Standard tolerances for CNC machining typically range from ±0.05 mm to ±0.1 mm, while injection moulding generally falls within ±0.1 mm to ±0.3 mm.

7. Flexibility

Injection moulding does not offer as much flexibility compared to CNC machining. This is because adjustments can be made easily with CNC machines as they only require altering the CAD file.

For injection moulding, the moulds can be amended easily, as it requires a new mould for any product changes.

CNC Machining Vs Injection Moulding: What Are The Similarities?

Aside from the differences, there are also similarities between CNC machining and injection moulding. Here are some of them:

- High precision: Both CNC machining and injection moulding can produce high-precision parts, but their methods differ. Injection moulding relies on the exactness of the mould cavity, whereas CNC machining depends on the controlled movement of its cutting tools.

- Diverse industries: They can be used in various industries such as automotive and electronics

- Produce complex parts: Both methods can handle complex designs. Injection moulding handles it through multi-component moulds. CNC machining utilizes 3-axis or 5-axis tool movement to create intricate geometries with high precision.

- Iterative design development: It can be used for prototyping and enables design iteration cycles

Choose The Best Manufacturing Method For Your Project

If you’re still uncertain about choosing between CNC machining and injection moulding, you can always reach out to us at ARRK Asia for help. Our team of experts is here to provide guidance and help you determine the best manufacturing method for your products. We’re committed to supporting you through every stage of product development.