Die Casting

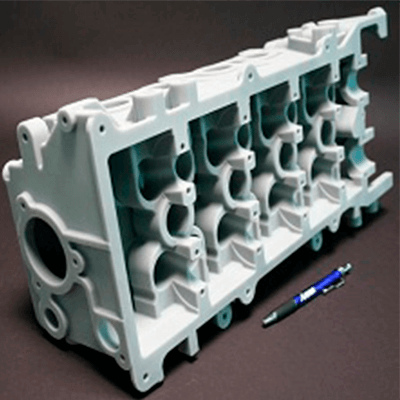

Die casting is a process that inserts molten metal under high pressure into reusable moulds called dies to produce high-quality components for multiple purposes. ARRK can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

Die Casting

Die casting is a process that inserts molten metal under high pressure into reusable moulds called dies to produce high-quality components for multiple purposes. ARRK can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

Home » Die Casting Manufacturer

YOUR EXPERT FOR DIE CASTING SERVICES IN ASIA

COST-EFFECTIVE

The valuable process to maintain quality standards and low cost

REPEATABILITY

Dies tools get used multiple times without sacrificing product condition

SHAPE AND MATERIALS

Complex shapes made with a wide range of metal alloys

CUSTOM COMPONENTS

FULL SERVICE

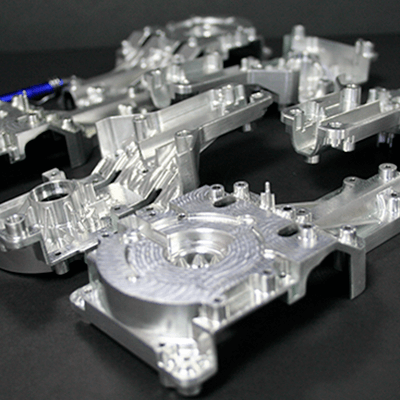

- Trimming, grinding, drilling/tapping, and CNC machining are part of our post-processing die casting services.

FINISH CHOICES

- Anodizing, liquid or powder painting, plating, painting, and graphics choices are available with the service.

Our Die Casting Metal Options

Choosing the right metal is a critical step in the die casting process, as it determines a part’s strength, weight, durability, and cost. At ARRK, we work with a wide range of alloys to meet the specific requirements of each project, ensuring the best material for every application.

Aluminium is one of the most widely used metals in die casting due to its excellent balance of properties. They are lightweight yet highly stable, with outstanding corrosion resistance. It is the material of choice for automotive components, electronics, and any application that requires strength without the added weight.

Key Advantages

- Excellent strength-to-weight ratio

- High thermal and electrical conductivity

- Strong corrosion resistance

- Fully recyclable

Zinc alloys are known for their castability and exceptional strength. They are ideal for producing complex components with thin walls and fine details. Zinc parts are also known for their durability, long die life, and impressive impact resistance.

Key Advantages

- High strength and hardness

- Excellent casting fluidity for zinc coating geometries

- Long die life

- Strong ductility and impact strength

Magnesium is the lightest die cast metal, making it the preferred option when weight reduction is critical. Despite its low density, magnesium offers a high strength-to-weight ratio and excellent stiffness. They are increasingly popular in the automotive, aerospace, and electronics sectors.

Key Advantages

- Extremely lightweight

- High strength-to-weight ratio

- Excellent machinability

- Effective EMI and RFI shielding

EXPERIENCE

Our Die Casting Package Solutions

From concept to completion, we offer die casting services. As a leading prototyping company in Asia, we deliver durable, high-quality parts across Malaysia, Singapore, and Thailand.

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

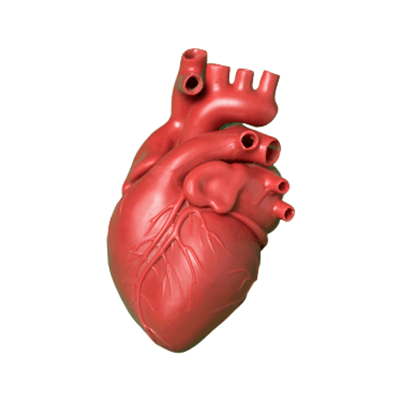

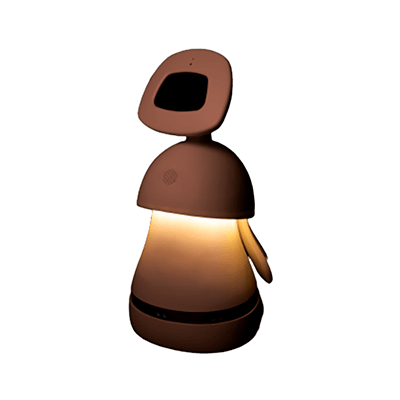

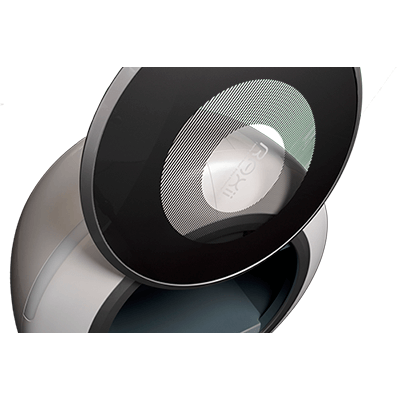

Applications of Die Casting Across Industries

Discover how we serve diverse industries with tailored die casting solutions. As a trusted product development partner in Asia, we deliver high-performance steel components to meet the needs of diverse industry applications.

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

How Safe Are EVs? The Engineering Behind Safer Vehicles

As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

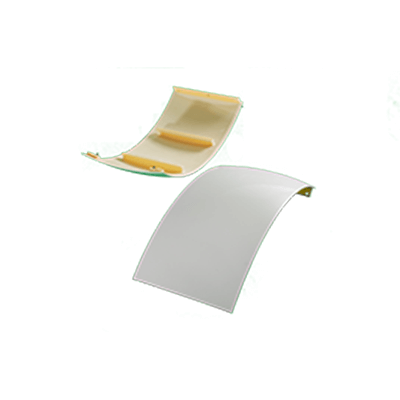

How to Solve Sheet Metal Fabrication Challenges?

Sheet metal fabrication plays an important role in industries such as automotive, electronics, EV infrastructure, and industrial equipment. Techniques like stamping aluminium, sheet bending, and metal pressing enable the production of a wide range of parts. However, these processes also present challenges that can affect precision, lead times, and costs.

WHAT DOES DIGITALISATION MEAN FOR MODERN MANUFACTURING?

Manufacturing today faces growing pressure for efficiency, flexibility, and quality. Digitalisation offers a powerful solution to optimise production, minimise downtime, and enhance supply chain visibility without significant increases in cost or workforce.

HOW DOES DIGITALISATION ENHANCE PRODUCT DEVELOPMENT TODAY?

In today’s fast-moving market, product development teams face the challenge of innovating quickly while maintaining quality and controlling costs. How can your business speed up development and achieve better results? The answer is digitalisation.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation

Begin Your Die Casting Journey With Us Today

Die Casting Frequently Asked Questions (FAQs)

Die casting is a process of forcing molten metal into a steel mould under high pressure. It is commonly used to manufacture high-strength metal parts with strong accuracy and smooth surface finishes. The industries that use die casting as industrial applications, electronics and automotive.

Die casting involves melting metal, such as aluminium, and injecting it into a steel mould at high pressure. After the metal cools down and becomes a solid texture, the mould opens, and the steel part is removed.

Aluminium, zinc, and magnesium are common die casting materials. Our team at ARRK Asia will recommend the best material according to the requirements.

Die casting can produce quality and durable metal parts at high speed. The components are strong and lightweight, suitable for industries such as electrical or automotive.

ARRK Asia is a professional product development company in Asia that provides die casting services, serving clients in Malaysia, Singapore and Thailand. ARRK Asia is known for delivering quality, high-precision metal parts that meet the standards of most clients in any industry. We specialise in providing aluminium die casting as it is the most common material that is in high demand.

Our Company in Asia

PENANG,

MALAYSIA

Sales Office

Ideal Avenue 1-3-12,

Medan Kampung Relau 1,

11900 Bayan Lepas, Penang, Malaysia

Tel: +604 638 1228

Pathum Thani,

THAILAND

Sales and Manufacturing

147 Bangkadi Industrial Park,

Bangkadi, Pathumthani

Pathum Thani 12000, Thailand

Tel: +66 2501 1170

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052

Kuala Lumpur,

MALAYSIA

Sales Office

Block E-10-01, Oasis Ara Damansara,

Jalan PJU 1A/7A, Ara Damansara,

47301 Petaling Jaya, Selangor, Malaysia

Tel: +603 7734 7692

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052