Sustainable Manufacturing Methods are the best options to solve most concerns when creating a product. This includes the business’ stability, the community’s healthy ecosystem, and the safety of everyone involved in the production, manufacturing, and supply chain.

How can companies integrate sustainable manufacturing?

It is safe to say that every company making everything possible to adhere to government and regulatory requirements is a start when having quality and lower risk to everyone in the production line. But, what else can be done?

- Make enhancements during the design phase: Design For Manufacturing (DFM) well used marks an important aspect of creating an efficient energy use, material selection, and substitution of energy and materials used. Therefore, working with manufacturers that incorporate DFM rules or have End-to-End services in Singapore can help follow good practices and minimize delays or additional costs.

- Efficiency in the design and prototype phase: Improvements done early on in the design and prototyping phases can help avoid wasting materials or the quality of the products. Recycling concepts have to keep a solid connection for the quality management your company needs to meet regulations and keep with customers’ expectations.

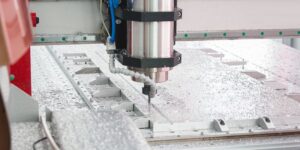

Implement advanced manufacturing strategies

Another option available for companies would be to adopt among the following manufacturing strategies:

- Lean Manufacturing: implementation of concepts and processes to remove waste from production, resulting in the most profitability without loss of quality.

- Agile Manufacturing: Having everything to respond to product changes quickly without loss of time or quality includes having the equipment capability and expertise in their team of designers, engineers, manufacturers, finishing team, and assembly line (if needed).

- Green Manufacturing: Term applied to production processes that minimize negative environmental impact by reducing waste. This can look different, like utilizing recycling, minimizing natural resource usage, and other efficiency-driven practices.

- Additive Manufacturing or 3-D printing: creates 3-D objects by building layers upon layers. This method is cost-effective and allows for efficiently making complex and lightweight products.

Become part of the companies that count on ARRK Asia’s expertise

Companies need to be up-to-date with manufacturing processes, and ARRK Asia’s team capabilities can help you decide the best path for your product manufacturing. Every service package comes with an optimized strategy for the type of industry your company has been established in.

If you want to call us for personalized attention, contact us at +60 3 7734 7692 or fill out our form to fill out our form to Get a Quote, we will be in contact with you to handle your questions on how we can assist your project.