Improving the low-volume production aluminum die casting process helps various industries, from industrial manufacturing to the automotive and aerospace industry. In fact, 80% of all automobiles produced today rely on some form of metal die casting technology.

ARRK Asia has seen some of the most common applications, including automotive engine blocks, cylinder heads, oil pans, transmission housings, and steering components. These castings require high precision, close tolerances, and exceptional surface finish. Let’s talk further about why aluminum die casting is used for low-volume production needs.

Benefits of Aluminum Die Casting for Low-Volume Production

ARRK Asia’s expertise can improve aluminum use in your manufacturing process. Aluminum is an ideal material for manufacturing small items like nuts or bolts due to its high strength per weight ratio. In addition, it makes low-volume production an important option for prototyping or high-mix low-volume orders.

Low-volume production helps streamline the entire process, eliminating redundant tools and reducing overall costs. Here are other reasons why your company should consider contacting ARRK Asia for your next aluminum high-mix low-volume aluminum die casting order:

High Strength-to-Weight Ratio

Aluminum is widely used as a material in manufacturing due to its high strength-to-weight ratio. Its unique features make it ideal for various applications, including aerospace, automotive, electrical engineering, consumer goods, food & beverage, packaging, plumbing fixtures, appliances, medical devices, chemical processing, transportation, building materials, etc.

It possesses many superior characteristics over traditional metals. These advantages include corrosion resistance, lightweight, good conductivity, excellent thermal shock resistance, and recyclability. Due to these attributes, aluminum is a popular choice for industries requiring precision machining.

Low Cost and High Quality

There have been many improvements recently that provide some significant cost savings compared to conventional metal stamping processes. One significant benefit of aluminum is that it offers much lower unit costs than competing materials, which makes it a more attractive option for budget-conscious businesses.

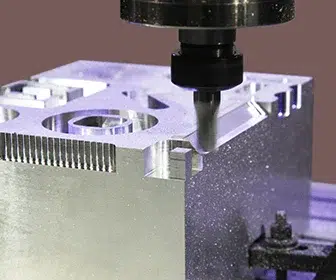

In addition, aluminum provides a higher level of quality products compared to competitors. At ARRK Asia, by using state-of-the-art technology, we ensure our customers receive the best possible results, resulting in top-quality parts at a fraction of the price of other technologies.

No Tool Changes

The only tool changes involved in manufacturing with aluminum are those necessary for forming the mold. No additional punches, stamps, or dies need to be changed after manufacture to produce different products. This eliminates costly downtime while waiting for tool changes and makes it possible to easily change molds without investing heavily in expensive equipment upgrades.

High Strength

Aluminum is stronger than steel and has greater tensile strength per weight. When it comes to manufacturing, this translates into strong and durable components that won’t fail under extreme conditions. The combination of high strength and light weight makes aluminum ideal for demanding industrial applications where durability is critical.

Easy Maintenance

Since there aren’t any moving parts inside an aluminum mold, it does not require regular maintenance. Instead, it just requires lubrication and cleaning before each cycle. This significantly reduces operational costs since machinery doesn’t need to be shut down for routine preventative maintenance.

Good Resistance Against Corrosion

Aluminum is highly resistant to corrosion and oxidation. Therefore, it resists rust and is easier to keep clean. Aluminum surfaces do not oxidize, unlike steel. As a result, aluminum components remain cleaner longer and eliminate the risk of contamination.

Recyclable

Most metals cannot be recycled and end up in landfills or incinerators. However, aluminum can be melted back down and reused. Since recycling aluminum saves valuable natural resources, it enables us to contribute positively to the environment.

ARRK Asia helps streamline the entire low-volume manufacturing process. With our extensive range of products, ARRK is the most suitable die casting manufacturer in Asia. We can help you with all design and manufacturing aspects, including tooling, machining, and assembly. Our team has over 40 years of experience working on small-volume projects where high quality and reliability are essential. So if you’re looking for a reliable partner, we can help you.