CNC Machining Service

CNC Machining Service

Home » Low Volume CNC Machining

WE USE ONLY THE HIGHEST QUALITY MATERIALS FOR OUR CNC MACHINING SERVICE IN ASIA.

We provide the highest quality CNC machining service to create optimal, precise prototypes or production parts faster, with our expertise covering Malaysia, Singapore, Thailand, and more countries throughout Asia.

CUSTOM OUTPUTS

Different elements that shape the desired design

VALUE FOR MONEY

Best economical solution for medium to low volume production

HIGH ACCURACY

Precise measurements for fine details

Our CNC Machining Service

At ARRK, we use advanced CNC machine to manufacture highly accurate and complex parts from a wide range of materials. With over 70 years of expertise, we deliver exceptional quality, speed, and consistency. We are your trusted partner for CNC machining solutions across Asia, including Malaysia, Thailand, Singapore, and more.

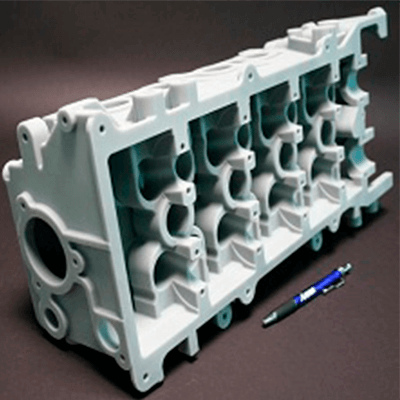

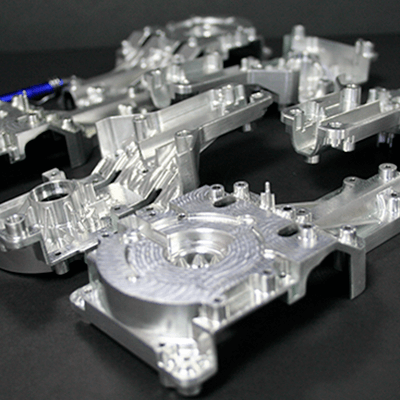

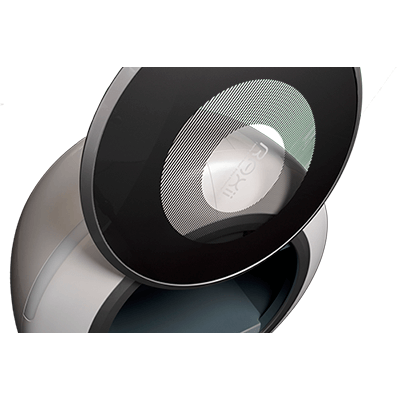

Our CNC milling process uses multi-axis machining tools to create precise three-dimensional parts. By removing material with rotating cutters, we can achieve complex geometries, detailed internal features, and smooth surface finishes. This capability is ideal for prototypes, custom tooling, and functional parts with tight tolerances, serving industries such as aerospace, medical, and automotive.

CNC turning involves rotating a workpiece while a cutting tool shapes it, making it the most efficient method for producing cylindrical components. Our CNC turning service delivers high precision and efficiency, enabling us to manufacture shafts, fittings, bushings, and other symmetrical parts with exceptional accuracy.

Our CNC laser cutting service provides a fast and cost-effective solution for producing precise shapes from sheet materials. Using a high-power, focused laser beam, we create intricate designs and clean edges with minimal need for secondary finishing. This makes it ideal for manufacturing flat parts, custom brackets, and complex patterns with high accuracy and reduced material waste.

For materials unsuitable for laser cutting, our CNC waterjet cutting service offers a powerful and versatile alternative. This process uses a high-pressure jet of water, often combined with an abrasive, to cut through almost any material without creating heat-affected zones. It is particularly valuable for applications where heat distortion must be avoided.

Our CNC Machining Expertise

Explore components produced with precision and care.

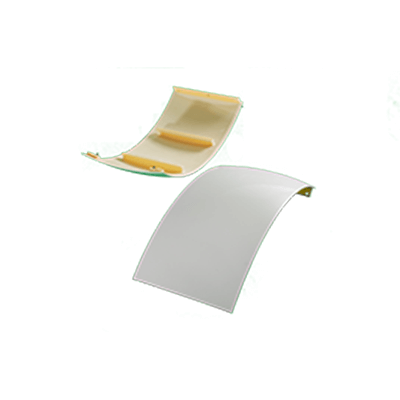

FINISHING SERVICES

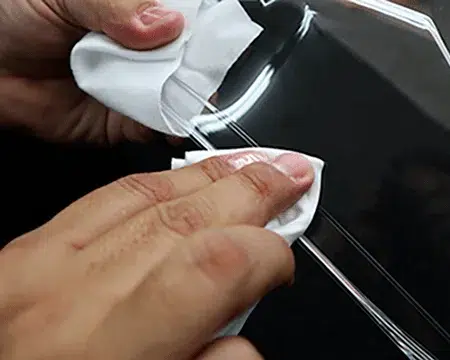

Perfect the look and performance of your CNC machined parts with our professional finishing solutions. From smooth, production-like surfaces to durable protective coatings, we ensure every detail meets your aesthetic and functional needs.

Achieve flawless surfaces with finishes ranging from matte satin to mirror gloss. Ideal for prototypes, presentations, or parts requiring clarity and reduced friction.

Simulate injection-moulded parts with a realistic, non-reflective texture. Perfect for consumer product prototypes and enclosures that demand a durable, uniform finish.

Enhance aluminium parts with a corrosion-resistant, decorative oxide layer. Available in multiple colors for lasting protection and appeal.

Create a tough, chip-resistant finish that outperforms conventional paint. Best for metal parts that require strength and durability.

Add a smooth, matte look while preparing surfaces for painting. A clean, uniform finish that improves both aesthetics and adhesion.

Customize your parts with brand-specific colors, gloss levels, or textures. A versatile finish for prototypes that need a final product look.

EXPERIENCE

Our CNC Machining Package Solutions

From concept development to final machining, ARRK Asia package solutions provides CNC machining service to bring your ideas to life with speed, precision, and consistency.

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

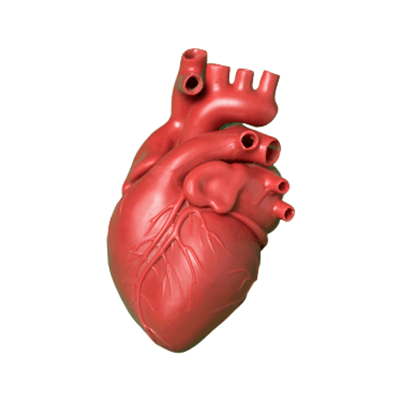

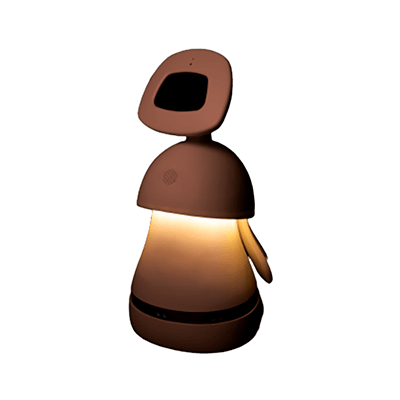

Applications of CNC Machining Across Industries

Discover how ARRK Asia CNC machining service provide a wide range of industries with precision-engineered components and reliable results.

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

How Safe Are EVs? The Engineering Behind Safer Vehicles

As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

How to Solve Sheet Metal Fabrication Challenges?

Sheet metal fabrication plays an important role in industries such as automotive, electronics, EV infrastructure, and industrial equipment. Techniques like stamping aluminium, sheet bending, and metal pressing enable the production of a wide range of parts. However, these processes also present challenges that can affect precision, lead times, and costs.

WHAT DOES DIGITALISATION MEAN FOR MODERN MANUFACTURING?

Manufacturing today faces growing pressure for efficiency, flexibility, and quality. Digitalisation offers a powerful solution to optimise production, minimise downtime, and enhance supply chain visibility without significant increases in cost or workforce.

HOW DOES DIGITALISATION ENHANCE PRODUCT DEVELOPMENT TODAY?

In today’s fast-moving market, product development teams face the challenge of innovating quickly while maintaining quality and controlling costs. How can your business speed up development and achieve better results? The answer is digitalisation.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation

Begin Your CNC Machining Journey With Us Today

CNC Machining Frequently Asked Questions (FAQs)

CNC machining refers to computer-controlled processes used to manufacture highly detailed parts. Whether for prototyping or production, CNC offers unbeatable accuracy and finish.

The CNC machining process begins with a digital design (CAD), which is translated into machine instructions. These instructions guide cutting tools to carve parts from raw materials.

There are a wide range of CNC machining materials such as aluminum, stainless steel, brass, and various plastics. We will guide on on how to choose the best materials for your product development.

Some of the benefits of CNC machining are fast, accurate, and scalable production. CNC machining reduces errors and delivers superior surface finishes compared to manual methods.

ARRK Asia is a trusted provider of CNC machining services, known for delivering high-quality parts with speed and precision. We tailor our solutions to meet your specific industry needs.

ARRK Asia provides CNC machining throughout Asia, delivering our expertise in product development and low-volume production in Malaysia, Singapore, Thailand and more. Contact us to know more!

Our Company in Asia

PENANG,

MALAYSIA

Sales Office

Ideal Avenue 1-3-12,

Medan Kampung Relau 1,

11900 Bayan Lepas, Penang, Malaysia

Tel: +604 638 1228

Pathum Thani,

THAILAND

Sales and Manufacturing

147 Bangkadi Industrial Park,

Bangkadi, Pathumthani

Pathum Thani 12000, Thailand

Tel: +66 2501 1170

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052

Kuala Lumpur,

MALAYSIA

Sales Office

Block E-10-01, Oasis Ara Damansara,

Jalan PJU 1A/7A, Ara Damansara,

47301 Petaling Jaya, Selangor, Malaysia

Tel: +603 7734 7692

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052