Injection Moulding Services

Our high to low volume injection moulding services allow companies to get as many custom parts as needed since this process’s main features are repeatability and competitiveness. Injection moulding works by injecting melted plastic into a mold, then cooling and solidifying it. This method provides solutions for low volume production.

Injection Moulding Services

Our high to low volume injection moulding services allow companies to get as many custom parts as needed since this process’s main features are repeatability and competitiveness. Injection moulding works by injecting melted plastic into a mould, then cooling and solidifying it. This method provides solutions for low volume production.

Home » Low Volume Injection Molding

YOUR EXPERT IN PLASTIC INJECTION MOULDING SERVICES

Achieve growth and productivity gains through our efficient manufacturing processes, supported by cutting-edge technology and comprehensive design and engineering. Our injection moulding solution offers a significant advantage as a low-cost manufacturing option, where the unit price drops as more parts are produced, and there is no minimum order quantity. This ensures accessibility and flexibility, while our quality and service network extends throughout Malaysia, Singapore, Thailand, and surrounding regions.

VERSATILITY

Production of small to large parts and low to high volume

MORE FOR LESS

The cost per unit is meager and tends to decrease

CUSTOM QUALITY

Highest standards with the best possible outcome

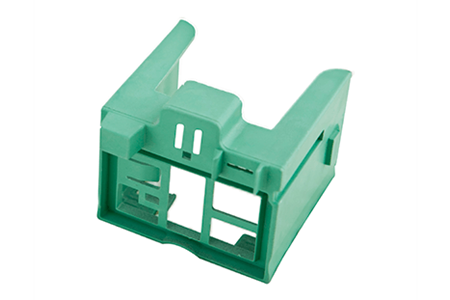

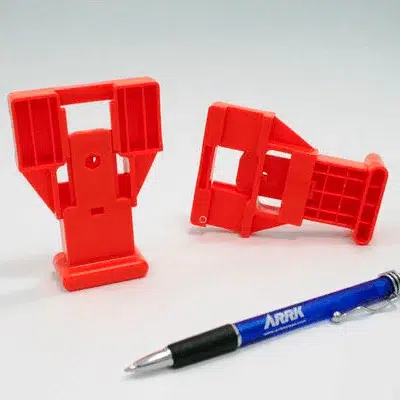

Our Plastic Injection Moulding Services

ARRK Asia is a product development company that provides various plastic injection moulding services to produce a wide range of materials, shapes and sizes.

Two Shot Moulding

This process uses a single machine with two injection units to mould a part from two different materials or colours in one cycle.

Insert Moulding

A specialised process in which a premade insert is placed into the mould, and plastic is then injected around it to form a single integrated part.

Over Moulding

Similar to insert moulding, this technique involves moulding a new layer of plastic over an existing component.

In-Mould Decorating (IMD)

In this process, a pre-printed film is placed into the mould before injection. When molten plastic is injected, it permanently bonds the graphic to the surface of the part.

Thin-Wall Injection Moulding

This technique uses high pressure and speed to fill the mould before the plastic cools, producing parts with very thin walls ranging from less than 1 mm up to around 2 mm.

Injection Moulding Capabilities

Specialised Moulding Services

We provide specialised characteristics and processes that compliments our injection moulding services to meet your prototyping needs.

INJECTION MOuLDING SERVICES

OTHER OPERATIONS

- Silk Screen / Pad Printing

- Laser Etching

- Painting

- Chrome Plating

- Powder Coating

- Ultrasonic Welding

- Heat Staking

- Thin Walled Parts

- Clear Parts

- High Polished Parts

EXCEEDING EXPECTATIONS

EXPERIENCE

Our Injection Moulding Package Solutions

At ARRK Asia, once your concept is defined, we take care of everything from prototyping to production. As a professional product development company in Asia, we specialise in full-service plastic injection moulding services.

Concept Design

Rough Sketch

Define Specs

Material Selection

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

BLOGS & NEWS

How Safe Are EVs? The Engineering Behind Safer Vehicles

As electric vehicles (EVs) reshape the way we drive, concerns remain over battery risks and fire hazards. This raises an important question: Are EVs truly safe?

How to Solve Sheet Metal Fabrication Challenges?

Sheet metal fabrication plays an important role in industries such as automotive, electronics, EV infrastructure, and industrial equipment. Techniques like stamping aluminium, sheet bending, and metal pressing enable the production of a wide range of parts. However, these processes also present challenges that can affect precision, lead times, and costs.

WHAT DOES DIGITALISATION MEAN FOR MODERN MANUFACTURING?

Manufacturing today faces growing pressure for efficiency, flexibility, and quality. Digitalisation offers a powerful solution to optimise production, minimise downtime, and enhance supply chain visibility without significant increases in cost or workforce.

HOW DOES DIGITALISATION ENHANCE PRODUCT DEVELOPMENT TODAY?

In today’s fast-moving market, product development teams face the challenge of innovating quickly while maintaining quality and controlling costs. How can your business speed up development and achieve better results? The answer is digitalisation.

TESTIMONIALS

Applications of Injection Moulding Across Industries

No matter the industry, ARRK Asia delivers precision manufacturing with professional services.

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation

Begin Your Injection Moulding Journey With Us Today

Injection Moulding Frequently Asked Questions (FAQs)

Injection moulding refers to the manufacturing process of producing plastic parts in large quantities. This can also be referred to as plastic injection moulding services. Injection moulding is commonly used in industries such as electronics and automotive.

The process of injection moulding involves melting plastic resin and injecting it into a mould. Once the resin has cooled, the mould will open, and the solid plastic parts will be removed from the mould.

There are various injection moulding materials such as polypropylene, polycarbonate and polyethylene. At ARRK Asia, we allow our clients to choose their preferred materials during the consultation phase. We have various materials to choose from and will provide guidance and advice on choosing the best materials for your project.

Injection moulding provides numerous benefits, such as quick production speed, cost-effectiveness, and the flexibility to customise the design based on the desired requirements.

ARRK Asia is a professional injection moulding company that extends their service across countries such as Malaysia, Singapore, and Thailand. We provides complete solutions to every client, ensuring all plastic parts are designed and produced according to the requirements.

Our Company in Asia

PENANG,

MALAYSIA

Sales Office

Ideal Avenue 1-3-12,

Medan Kampung Relau 1,

11900 Bayan Lepas, Penang, Malaysia

Tel: +604 638 1228

Pathum Thani,

THAILAND

Sales and Manufacturing

147 Bangkadi Industrial Park,

Bangkadi, Pathumthani

Pathum Thani 12000, Thailand

Tel: +66 2501 1170

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052

Kuala Lumpur,

MALAYSIA

Sales Office

Block E-10-01, Oasis Ara Damansara,

Jalan PJU 1A/7A, Ara Damansara,

47301 Petaling Jaya, Selangor, Malaysia

Tel: +603 7734 7692

SINGAPORE

Sales Office

18 Ah Hood, #08-51, Hiap Hoe

Building at Zhongshan Park,

Singapore 329983

Tel: +65 6992 8052