Synopsis

The National University of Singapore (NUS) is one of the most prestigious academic institutions in Asia and the world. Formerly known as the Straits Settlements and Federated Malay States Government Medical School, the university was founded in 1905. Today, NUS offers degree programs at both undergraduate and postgraduate levels in a wide range of disciplines, from science, sociology, and literature to other fields of academics. In addition, it continues to provide world-class academic service to international students and researchers, contributing a high level of modern technology and science research to society.

Moreover, health science keeps growing, and researchers from NUS are working hard to develop new technologies to aid in the search for more accurate results. But before each product becomes a reality, it takes lots of trial and error. And that is why prototypes are key in the experiment’s validation process.

A Long and Loyal Partnership

For this project, Stephanie Yap, a postgraduate researcher at the NUS Nanolab, became ARRK’s customer since she was working at the National Technological University. Stephanie was looking for a vendor to help her design a device that would be used for testing neurological conditions. Since accuracy and high quality were vital, she contacted our engineering team. We gladly agreed and started the process as a research partner with a clear objective: developing a high-definition prototype.

The Challenges

The existing design done by another vendor had several issues that needed to be resolved or improved on, such as:

- A closing hinge design with slight rotational and lateral movements that could not ensure an accurate alignment with the probes and the microchip on the lower base;

- Water sealing was not ideal;

- The position of probes might not have been stable and accurate;

- A small window for viewing the liquid sample introduced onto the microchip.

The Solution

Our engineering team saw the existing prototype, listened to Stephanie’s requirements and concerns, and redesigned the parts.

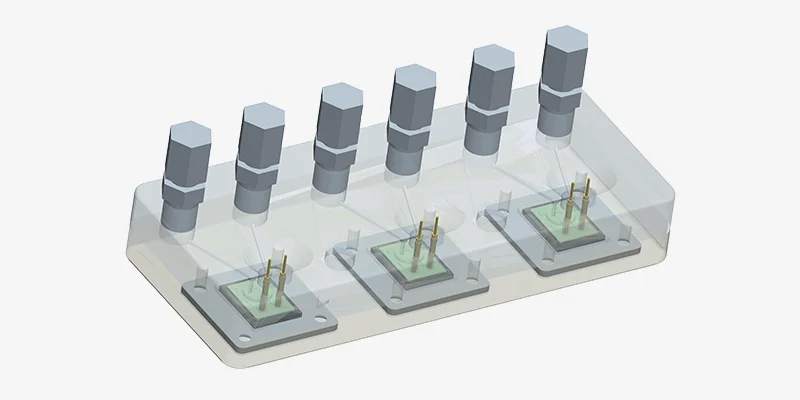

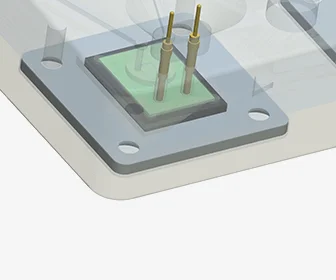

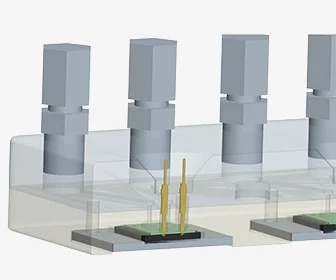

Firstly, we needed to eliminate any moving parts that could compromise positional accuracy. In this case, the hinge was removed, and the design was simplified to just a single acrylic case with a bottom cover to secure the microchip in place.

The positions of the probes were also improved as there were no moving parts to align them to the microchip.

To tackle the water sealing issue, two acrylic blocks were glued together so that the flow of the liquid channels to the microchip was continuous and did not split.

The gluing of the acrylic blocks was meticulously done so that the transparency of the acrylic was still retained, allowing for the entire liquid flow process to be seen without any restrictions like the small window in the previous design.

The cleaner overall design also allowed for more space savings, and we were able to accommodate and implement three separate microchips to test three liquid samples at the same time compared to the existing prototype, which could only test one at a time.

At ARRK, we strive to meet customer requirements with our design know-how, making the experiment tool reliable, precise, and trustworthy.

Final Result

After delivering the prototype, the customer conducted many tests and evaluations. Feedback was excellent as the prototype was simple and easy to use and had no inherent issues that could compromise the end result. As such, Stephanie was able to conclude her research successfully, and her work was eventually published in the medical journal Small 2022.

At ARRK Asia, our customers are our number one priority. By carefully listening to their needs and providing exceptionally proficient results, we will always find a way to ensure their ideas come to fruition successfully and professionally. Furthermore, we have partner factories around Asia, so we can provide a wide range of quality services in terms of expertise and lead time.

In addition, we continuously provide an innovative variety of services. We are research partners to help your experiments run smoothly and to make your ideas come true. Our team of experts is ready to provide consultation and aid in beginning your project. Get additional information about Product Design and CNC, as well as the materials and finishing options we offer. Contact us by phone at xxx-xxx-xxxx, get to know us, or get a quote to be contacted directly by our Business Development team.