Selecting a 3D printing service in Asia provider is a better option than buying your 3D printing machine. There are also many advantages to using 3D printers compared to traditional manufacturing. There is a way of taking advantage of 3D manufacturing for what your company needs on its own, but is it the best option?

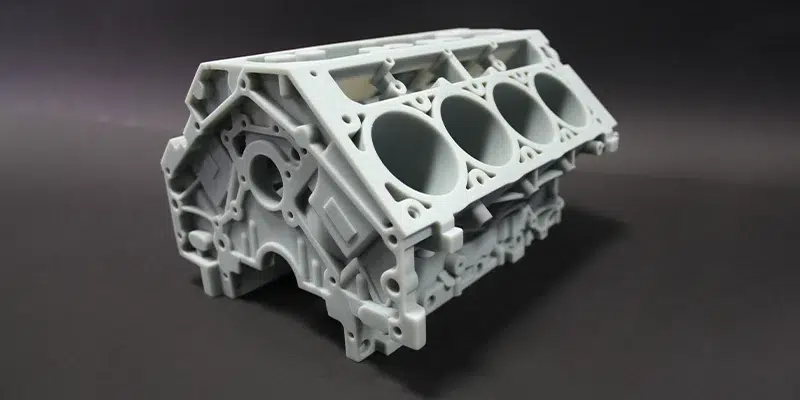

Some 3D printers are portable, allow for complex shapes that don’t need assembly, and involve cheap materials. You can also use 3D printers to make objects too small or quirky for mass production and suffer from less material loss than other processes.

Putting these three options in comparison:

- Traditional manufacturing

- Self-taught 3D printing

- Professional 3D manufacturing service

We can show the benefits of why it is better to choose a 3D printing service in the end.

Traditional manufacturing vs. 3D printing

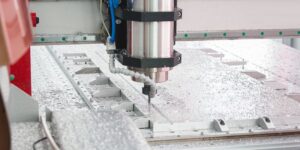

There has to be a long line of production steps to deliver the finished product to market. Traditional steps are better known as a subtractive manufacturing process, making it a place that shows how much anyone could save materials.

Key points to determine which type of manufacturing is better for managing the company’s time and budget are:

- Production volume

- Customizability

- Complexity of shapes

In the manufacturing industry, improving new techniques are constantly being tested, significantly to lower the cost of production, optimize material usage, lower energy consumption, and expand their capability. However, some requirements will need to be considered, like Quality Assurance and Quality Control.

For all these reasons, changing to a 3D printing service can help your company in the long term.

Self-taught 3D printing vs. 3D printing service

Having the goal of building functional and high-fidelity prototypes can make doing your 3D printing a difficult task:

- The general public markets have detected a lack of economy of scale in mass production of 3D parts, which some objects are more expensive to produce than buying them.

- There is also the situation with the availability of materials for the general public. It can be challenging for beginners to compete with the best professional 3D printing manufacturers because they don’t have access to a wide range of materials.

- Another strong point that could hinder jumping into 3D manufacturing on your own is a lack of professionally trained personnel. Unfortunately, finding a person that has the experience to be ready for any situation is not easy.

- The learning curve is immense and never-ending, and in challenging circumstances, this can affect the lead times of not just one project but all the projects in your company. However, having experience handling 3D files, complex geometries, selection of plastic materials, design iterations, and much more is part of what builds into High-Quality products.

- The entire process for the finishing would be left out, leaving surface finish and functional prototyping in Singapore out of the possibilities for your company.

Having a better understanding of your manufacturing process could change for the better, but putting in perspective the experience of a team as an ally will make the best of 3D printing for your company’s production goals.

Use the advantages of 3D printing services to your benefit

It all comes down to the different applications you need for your part and the production run volumes.

In ARRK Asia, we count on an incredibly experienced team, which knows the trade and gives the best advice to match your expectations and production needs. In addition, we understand well the rapidly changing market demands and how that affects your business.

ARRK Asia is an example of having a good team of designers, technicians, craftsmanship, and sales representatives that know their craft, people who have experience and up-to-date knowledge.

Get in contact with us today to see how we can help your team keep projects on schedule.