Do you want to create a 3D model of a new product or prototype? If so, you should consider a 3D Printing service in Asia using Silicone Rubber Mold manufacturing. At ARRK Asia, we know this method is widely used in industries such as Automotive, Electronics, Aerospace, Medicine, and Food & Beverage with amazing results. Why would ARRK Asia’s experts choose silicone rubber over other types of molds for your project? Let us tell you why.

Silicone Rubber Mold Manufacturing for Your Next Production

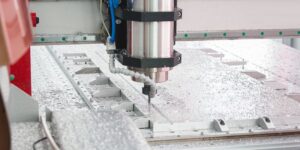

Silicone Rubber Mold Manufacturing (SRM) is a plastic manufacturing technique where the object is created using a combination of heat and pressure. This process is similar to Injection Molding, but in this manufacturing process, we are capable of creating complex shapes without having to cut away material.

The process of SRM uses the material to create molds for casting plastics and metals, allowing the many advantages of using silicone rubber over traditional methods to your project’s favorable outcome.

Silicone rubber is widely used in many industries due to its non-toxic, non-flammable, and highly resistant-to-chemicals properties. Nowadays, SRM is increasingly popular for Small-Lot Production. This is thanks to silicone rubber molds providing high dimensional accuracy and an excellent surface finish, which creates prototypes with the final product’s finish, look, and function.

The manufacturing process also exhibits good mechanical properties like hardness, abrasion resistance, chemical stability, and low shrinkage, making it the best choice possible for products with complex features and specifications from other manufacturing companies.

How Companies Have Successfully Used Silicone Rubber

- Silicone Rubber Products

Food manufacturers use silicone rubber molds to make their popular snack foods. This helps the company produce consistent shapes and sizes while maintaining the quality of the snack.

- Medical Devices

A good example of how silicone rubber is used in the Medical Device Industry is catheters, commonly used in hospitals and doctors’ offices to treat conditions such as heart disease, cancer, kidney failure, and diabetes. It creates a perfect shape and size for each catheter. This makes it possible for healthcare professionals to easily insert the catheter into the patient without causing damage to the surrounding area.

- Automotive Parts

Car manufacturers have integrated silicone rubber manufacturing into producing several parts for their vehicles, including the interior and exterior trim pieces. The vehicle manufacturer has been able to do this because silicone rubber is durable and lightweight. Additionally, silicone rubber is highly resistant to weathering, scratches, fading, and UV rays. As a result, they have reduced costs associated with repairing damaged parts.

ARRK is the Preferred Choice for Production

Today, manufacturing is changing rapidly. In order to survive in today’s competitive environment, manufacturers need to adopt innovative technologies. New technologies such as 3D printing, robotics, AI, IoT, and automation are revolutionizing how companies manufacture goods.

Manufacturers who embrace innovation will thrive. Therefore, the best option for choosing the best manufacturing method and Rapid Prototyping Model in Asia is ARRK. When working with our team, we will help you implement new ideas into your production and assist you in developing prototypes and products with the latest technology.

To produce high-quality silicone rubber molds, it is best to contact ARRK’s team of Rapid Prototyping experts. Our entire production line can make a fine surface finish, and its unique design allows for easy cleaning with little or no damage to the molded part. Contact us to get a quote!