Rapid prototyping (RP) refers to several methods and techniques used to create 3D models from Computer-Aided Design (CAD) drawings. The purpose of RP is to reduce the time required to develop new products or improve existing ones. It is also a way for engineers to visualize designs prior to starting manufacturing.

Rapid prototyping materials allow designers to create a model that looks like a finished product. It helps them get a preview of the final product and check the proportions, colors, and textures of the product. Choosing the right material can save costs and time spent in the manufacturing process.

ADVANTAGES OF RAPID PROTOTYPING ADVANCED MATERIALS

Rapid prototyping (RP) technology has been around since the 1970s. The term was first coined by Donald Brown in 1974 at MIT’s Lincoln Lab. In short, RP provides a cost-effective method to create three-dimensional objects from digital data using various processes that cut through layers of material. This technology can be used for metal casting, plastic molding, dental implants, microelectronic devices, and even printing organs like human hearts.

The advantages of RP are numerous, among them are the following:

- This technology allows designers to iterate quickly without investing a great deal of time and money into building prototypes.

- It enables designers to focus on higher-level design decisions rather than spending time creating technical details.

- RP decreases the cost of manufacturing, as the majority of production steps are automated.

- It creates a model ready to use right out of the box, eliminating many of the costs associated with traditional prototyping methods.

The ability to make prototypes much faster and cheaper than traditional methods makes rapid prototyping more attractive to manufacturers who want to preview the features of a product before they approve a high-volume manufacturing project.

Also, companies that traditionally manufacture mass quantities of identical products may find that RP enables them to customize their designs and offer unique products to customers. With the best advice, your product will get the best choice of materials and the mechanical properties you are looking for, such as the following:

- Functional properties

- Fatigue strength

- Ability to handle glass transition temperatures

- Test material extrusion rates

- Measure tensile strengths

- Access to thermoset materials

UNLIMITED DESIGN POSSIBILITIES WITH ARRK ASIA’S PRODUCT DEVELOPMENT TEAM

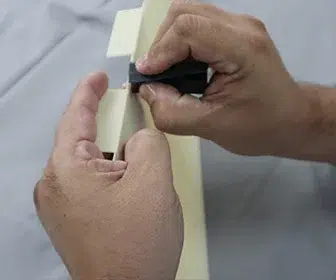

RP can use simple tools like a laser cutter, 3D printer, CNC mill, or waterjet cutter. These machines allow individuals to easily produce small quantities of parts at a time. This makes RP ideal for creating a variety of products that are not necessarily large in scale. In addition to being inexpensive, RP can be completed at a much faster rate than traditional methods.

When contacting ARRK Asia, the whole team can help your company prototype new ideas and concepts much quicker than if they had to wait weeks or months to receive their order for other manufacturing techniques available.

RP does not limit users to only using certain design elements. As the industry advances, we see more and more possibilities for creating new and exciting products. If you are looking to get something made quickly and cost-effectively, then RP might be your best bet. If you want to go big, ARRK Asia offers End-to-End Manufacturing services to create high-quality products.