Ever wonder how safe your daily appliances are, such as coffee brewers and food containers? What type of requirements must the prototyping process uphold?

When developing prototypes for products intended for food contact, manufacturers must adhere to numerous requirements and testing to ensure the use of safe materials. Food-grade materials are those that not only perform effectively but also comply with stringent safety standards to ensure consumer protection.

This article explores the important requirements of food-grade product development and how ARRK can optimise the prototyping process to meet these standards.

FOOD GRADE MATERIAL REQUIREMENTS

Regulatory Standards and Certifications

The primary factor in determining whether a material is safe for food contact is its compliance with regulatory standards, which can vary by country.

- FDA Approval

- In the United States, materials that are tested and must adhere to guidelines set by the Food and Drug Administration (FDA) are considered safe for food contact. Compliance with specific regulations, such as 21 CFR Part 177, which governs indirect food additives.

- EU Regulations

- In Europe, materials must meet the requirements of Regulation (EC) No 1935/2004. This regulation ensures that materials used in food contact applications do not release harmful substances into food, safeguarding consumer health and safety.

Material Properties and Composition

- Chemical Inertness

- Materials should be chemically stable and resistant to reactions with food substances. For example, if the material is unstable under certain conditions, it could result in tiny particles being transferred directly into the product intended for consumption.

- Non-Toxicity

- The material must not contain toxic substances or heavy metals that could migrate into food. This is particularly important for plastics, which can sometimes release harmful chemical compounds if not carefully engineered.

Testing and Validation

- Migration Testing

- Migration refers to the transfer of molecules from materials into food. This is typically assessed using six different simulants that represent the properties of various actual foods.

- Sensory Testing

- Evaluates whether the material affects the taste, odour, or appearance of the food.

- Temperature Resistance

- It assesses the material’s ability to maintain safety, integrity, and performance under various temperatures and conditions, including cooking and freezing.

Cleaning and Durability

- Easy to Clean

- Materials should be non-porous and resistant to staining and microbial growth to facilitate effective cleaning and sanitation.

- Durability

- The material should withstand physical wear and tear, including impacts and abrasion, without compromising its safety or integrity.

Food Contact Conditions

- Acid and Base Resistance

- Some foods are highly acidic or basic, which can affect certain materials. Testing ensures that materials do not degrade or release substances under these conditions.

- Fat Resistance

- Materials should be resistant to fat and oil, which can otherwise affect their stability and safety.

WHY CHOOSE ARRK FOR FOOD GRADE MATERIALS?

Are sky-high tooling costs for FDA materials slowing down your prototyping process? In the fast-paced world of food grade manufacturing, understanding and adhering to regulations is crucial for ensuring both safety and quality. ARRK offers game-changing solutions to meet product specifications and timelines.

Cost-Effective

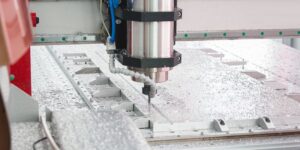

ARRK provides food-grade prototyping services such as CNC machining and vacuum casting services, using materials that are both cost-effective and efficient. Our advanced rapid prototyping capabilities enable us to use food-grade materials like PU ABS (V4), to produce high-quality parts.

We possess vast knowledge of the essential requirements for achieving FDA-compliant plastic parts, eliminating the need for costly traditional tooling. This flexibility allows customers to refine and manage multiple design iterations and components without incurring substantial costs.

Shorter Lead Times

We have the ability to deliver prototypes in a shorter span of time. Our streamlined approach provides the most suitable food grade materials and processes to meet tight deadlines and expedite development.

Our team of experts and extensive experience ensure solutions that reduce lead times and help bring new products to market faster. This efficiency allows for more comprehensive testing and evaluation, enabling a swift response to market demands and consumer preferences.

Tailored Food Grade Solutions

Food appliances and equipment come with unique requirements and visions, and we are here to meet those needs. Our selection of food grade materials can be customised to achieve the specific durability, strength, and requirements for food grade parts.

Food grade materials have undergone testing and validation to ensure optimal performance. We offer materials to develop components that help our customers’ appliances stand out and excel in the market.

Highly Refined Prototypes

Our commitment to providing prototypes that closely match final production materials ensures high fidelity to the end product. This alignment with real-world applications facilitates thorough testing, validation, and refinement of the concept design.

It ensures that the final product meets all performance and safety standards. By utilising materials that replicate the properties of the finished product, we help our customers identify and resolve potential issues early in the development process.

ARRK’s extensive experience in rapid prototyping of consumer products ensures that your food-grade prototypes and components meet the highest standards of safety, performance, and reliability.

Partner with us to bring your food-safe innovations to life with efficiency and confidence. Reach out for a quote to get started!