From advances in medical research to building houses, 3D printing has changed our lives forever, allowing us to create almost anything from scratch. Rapid Prototyping is gaining popularity due to its ability to produce complex geometries at low costs and high quality, and ARRK Asia’s team stands out from other companies due to its expertise.

At ARRK Asia, we use Additive Manufacturing Laser Sintering technology to create viable and workable applications in various fields, such as Aerospace, Automotive, Biomedical Engineering, Robotics, Defense & Security, Consumer Goods, and Energy industries.

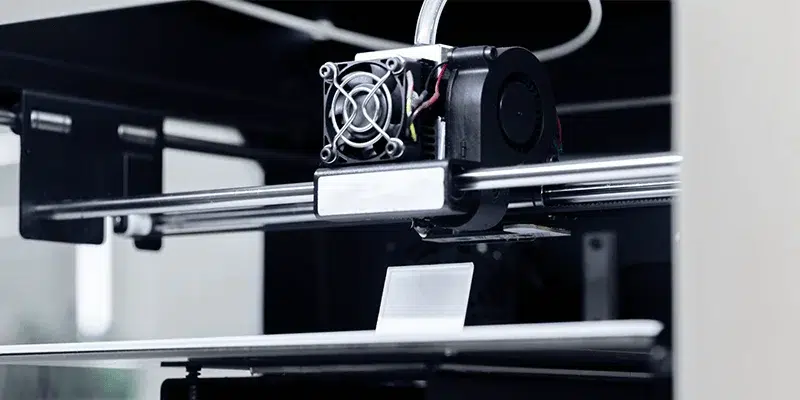

How Does 3D Printing Work with Laser Sintering?

3D Printing Additive Manufacturing combines layers or parts through Selective Laser melting, electron beam melting, powder bed fusion, or direct metal deposition to create 3D objects. The machine uses lasers or electricity to fuse layers.

There are two types of 3D printing technologies. They include Selective Laser Sintering (SLS) and Selective Laser Melting (SLM).

- SLS uses a high-intensity focused beam of light to melt powder particles into a molten state. Once melted, the powder cools down and bonds together, forming a solid structure.

- SLM uses a high-power laser beam to heat metal powders and form objects.

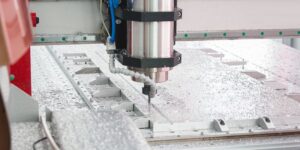

Cut Down Costs Without Compromising Quality

While traditional machining and casting remain the primary method of producing engineered components, today’s engineers must consider new ways of making these objects with 3D printing technology. This includes considering alternative designs, materials, and manufacturing processes.

What are the advantages of Selective Laser Sintering and Selective Laser Melting technology are two ways to cut production costs without compromising quality. In addition to saving time and resources, it also enables manufacturers to produce highly accurate components at a low price.

Which one should you choose? SLS and SLM can produce parts from a wide range of materials, such as stainless steel, titanium, aluminum, brass, copper, nickel, cobalt, iron, zinc, magnesium, gold, silver, platinum, palladium, rhodium, iridium, osmium, and tungsten.

Custom-made Solutions to Meet All Your Needs

Additive manufacturing allows us to create components with more complex shapes than ever before, and our expertise provides us with the capability to manufacture functional prototypes quickly and accurately.

We have developed reliable products and services over time with the support of our clients, and we take pride in providing high-quality services. If you want to start your project with either technology, contact ARRK Asia’s team for more information. We offer an outstanding 3D Printing service in Asia that will meet all your needs.