Selective Laser Sintering (SLS) has recently gained popularity due to its ability to produce complex parts at low costs. So what are the advantages of Selective Laser Sintering over other 3D printing technologies and End-to-end Prototyping in Asia?

At ARRK Asia, we have seen this method allowing companies faster production times and better resolution than other types of 3D printing technologies. Let our experts guide you through what each technique offers. We can detect the unique benefits and drawbacks depending on the type of part you need to be printed.

Selective Laser Sintering

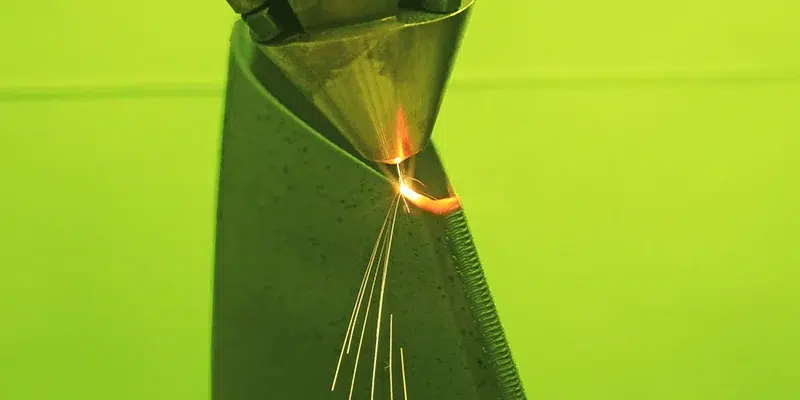

Selective Laser Sintering (SLS) is a 3D printing technique in which plastic or metal powder is fused using a high-powered laser beam. The resulting parts are stronger than their conventional counterparts because they are made from individual particles rather than layers. In addition, the material properties can be precisely controlled.

Advantages of Selective Laser Sintering

- Eliminates Waste

With Selective Laser Sintering (SLS), there is no need for molds and dies, thereby eliminating the production of scrap material and resulting in minimum tool wear. This means less waste and fewer costs associated with mold design, tooling, and manufacturing.

- Reduces Manufacturing Time

With SLS, the time-consuming steps of mold making and die casting are eliminated, resulting in reduced manufacturing times. In addition, the number of individual units produced per hour increases dramatically compared to other methods, increasing productivity.

- Improves Quality and Costs

Since no molds, dies, or tools are involved in manufacturing products, the quality is better than conventional processes. Also, significant cost savings are associated with producing prototypes and small runs. Additionally, the speed at which prototype samples are manufactured reduces lead times considerably.

Applications of Selective Laser Sintering

Additive Manufacturing Laser Sintering produces high-quality parts that conform well to shape requirements without requiring post-processing steps. This makes SLS ideal for creating prototypes and functional testing, making it the reason for its several applications in the following industries:

- Medical Applications

SLS technology was first developed in the 1980s to manufacture metal prosthetics. Since then, its application has grown significantly due to its versatility. The medical applications of Selective Laser Sintering (SLS) have expanded to include products such as dental implants, bone replacements, hip joints, and even custom-made hearing aids. In addition, SLS printers have been used to create prototypes for surgical instruments and tools. These examples demonstrate how the potential uses of SLS continue to expand and improve healthcare.

- Aerospace Technology

In recent years, aerospace technology has become increasingly dependent on additive manufacturing processes. As a result, the demand for production equipment capable of producing complex parts at high speeds has increased dramatically over the past decade. Due to its high precision and speed, SLS technology has played a significant role in the advancement of aerospace technologies.

- Industrial Applications

Industrial applications of SLS printing include creating tools and machinery, such as tool bits for drilling machines and industrial components requiring high precision, like gears, bearings, and other mechanical parts.

Creating Functional Prototypes

As a manufacturer with expertise in 3D Printing service in Asia, ARRK understands the challenges it implies. Our team of experts understands how complex manufacturing processes often leave room for error, making our End-to-End methodology a counteractive way to plan for any possible issue.

At ARRK Asia, we are proud of our reputation as an innovative company that works closely with our customers to make sure they get exactly what they want. Our team offers exceptional service and support and is always available to answer your questions. Contact us for more information!