Need just the right number of parts without going overboard? Low-volume manufacturing provides a strategic approach that combines speed and flexibility, making it especially effective for producing prototypes or specialised parts. However, it’s important to understand the potential challenges and how to navigate them effectively.

WHAT IS LOW-VOLUME PRODUCTION?

Low-volume production refers to the manufacturing of a small quantity of parts or products, typically ranging from a handful to a few thousand units. This production model is ideal for businesses needing custom designs, prototypes, or limited-edition items.

Unlike mass production, which is optimised for high quantities and efficiency, low-volume manufacturing focuses on flexibility, quality, and the ability to make design changes or versions quickly. While it allows for a more tailored approach, it comes with its own set of challenges, such as high initial tooling costs, supply chain complexities, and customisation demands.

STRATEGIES FOR LOW VOLUME MANUFACTURING CHALLENGES

1. High Initial Tooling and Setup Costs

Low-volume production often avoids the high overhead of mass production, but the initial tooling and setup expenses can still be surprisingly significant. This is particularly true for projects that involve custom designs, intricate geometries, or specialised components that necessitate unique moulds or fixtures. When initial tooling costs are spread over fewer units, this can result in a higher cost per unit, especially if multiple design iterations are needed.

Solution: Leverage Prototyping Techniques for Short Runs

A significant cost reduction can be achieved by combining rapid prototyping methods and a cost-efficient tooling approach. Low volume CNC machining, die casting, 3D printing, vacuum casting, or silicone rubber moulds are ideal for producing small batches without the need for expensive tooling, making them suitable for early-stage validation and fast iterations.

When slightly higher volumes are required, switching to soft tooling such as silicone rubber moulds or aluminium moulds offers a more affordable and quicker alternative to traditional steel tooling. This strategy enables manufacturers to reduce initial costs and preserve adaptability while producing high-quality parts in smaller quantities.

2. Customisation and Iteration Requirements

One of the key advantages of low-volume production is the freedom to tailor designs, test new concepts, and refine details without the constraints of mass production. However, this flexibility often involves certain trade-offs. Unique specifications, one-off finishes, or material changes can quickly lead to longer lead times, repeated revisions, and added cost if not managed properly. Customisation can become a bottleneck without the right strategy.

Solution: Experienced Guidance on Complexity

This is where experienced manufacturing guidance becomes critical. A skilled team does more than just execute orders. They actively evaluate your design goals, budget, and timeline to recommend the most effective path forward. Whether you are refining a prototype or customising a functional part, their insight can help reduce unnecessary iterations and prevent production issues before they arise.

Their expertise in manufacturing technologies allows them to identify the most suitable options for your specific needs, removing the uncertainty that comes with a trial-and-error approach. They carefully evaluate material properties, surface finish, and cost efficiency to achieve the ideal balance between customisation and production speed.

3. Limited Material Selection and Availability

Sourcing suitable quantities of specific materials can pose challenges, particularly for specialised grades like food-grade, heat-resistant, or fire retardant. These materials may have extended lead times, particularly if they are imported or available from a limited number of suppliers.

Inconsistent availability can cause production delays, force last-minute design changes, or compromise product quality if the chosen material turns out to be incompatible with the manufacturing process. These complications can have a domino effect on project timelines, costs, and overall reliability.

Solution: Strategic Material Sourcing

Having a wide range of materials is very helpful when selecting the best material and staying within budget. Working with partners who offer diverse material choices ensures that product performance is not compromised, while also making procurement faster and more efficient.

Their expertise helps evaluate which materials are most suitable based on design requirements, functionality, and availability in smaller quantities. This support creates confidence that the material chosen fits well with the manufacturing method and delivers the desired surface finish for the final product.

4. Managing Quality Consistency

Quality consistency can be difficult to maintain in low-volume production due to the lack of standardised, automated processes often seen in mass manufacturing. This is especially true for customised or niche products that require more manual intervention, tight tolerances, or specialised skills to produce accurately.

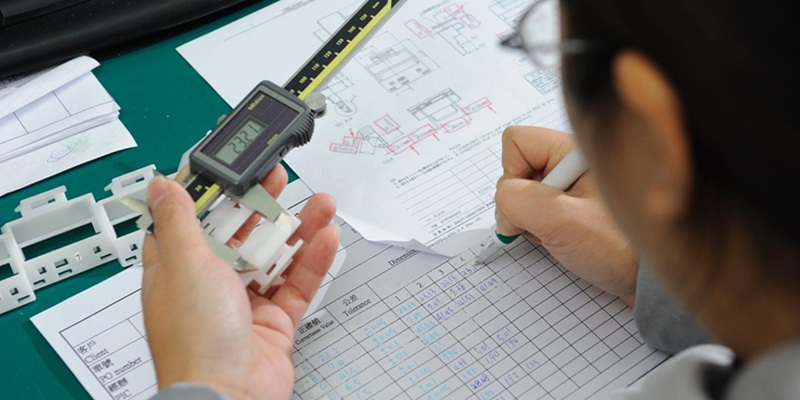

Smaller batches may rely on manual quality checks or limited sampling methods, increasing the risk of subtle defects being overlooked. Experienced technicians and strict quality control are essential for consistent part specification.

Solutions: Implement Oversight and Quality Control Measures

An experienced team will foresee and address potential problems caused by material properties, mould changes, or process constraints. Quality assurance practices, such as using pin gauges to verify precise dimensions and employing Coordinate Measuring Machines (CMM) for detailed inspections.

Even for limited production, thorough documentation, standardised operating procedures, and detailed quality control checklists are essential. Quality management systems ensure that despite smaller quantities and extensive customisation, consistent quality is maintained throughout production.

5. Supply Chain Complexity

Supply chain complexity in low-volume production can introduce a variety of challenges that affect cost, lead times, and overall product quality. Delays are common, often caused by extended lead times, customs clearance complications, or unpredictable delivery schedules, particularly when sourcing materials from international suppliers. Miscommunication between stakeholders can further disrupt coordination, leading to setbacks and potential issues throughout the production process.

Solution: Get a Partner with Supply Chain Expertise

Experienced suppliers bring valuable insight into international customs and logistics protocols, ensuring every step is accounted for to prevent delays and unexpected fees. Their understanding of regional requirements allows for better planning of production and shipping schedules, helping to keep projects on track.

They work closely with freight forwarders and couriers that are familiar with handling various types of items, which reduces the risk of transit damage or delays. The determination of the most efficient delivery method, route or courier can make a huge difference in shipments within the lead time. Gain more control and understanding with their logistics expertise to minimise disruption and stay within both time and cost expectations.

SIMPLIFY LOW-VOLUME MANUFACTURING

The right partner can turn low-volume manufacturing challenges into valuable opportunities. At ARRK, we specialise in navigating these challenges and aim to execute reliable solutions at every stage, backed by over 70 years of experience.

Need insights for your low-volume production project? Reach out for a consultation today!