Prototyping is a process that allows manufacturers to test their products before they are mass-produced. This helps them understand how their product works, what adjustments need to be made, and how to improve its design. In order to create prototypes, manufacturers use different materials like plastics, metals, ceramics, and more.

Different manufacturing industries need different materials for making prototypes due to their set goals. Each material has its advantages and disadvantages, for example:

- Plastic is lightweight and inexpensive but can break easily when subjected to excessive force.

- Metal requires special tools to work with. It is strong and durable, which makes it impossible to be used on items that need to bend or have a certain elasticity.

DIFFERENT USE OF PROTOTYPING MATERIALS IN THE MANUFACTURING INDUSTRY

Prototyping materials are essential for any product that needs to be manufactured before mass production. They are used to test out different designs and components of a final product. For example, in the case of electronics, they can be used to test whether or not the circuit board works correctly.

Here are different prototyping materials and their usage:

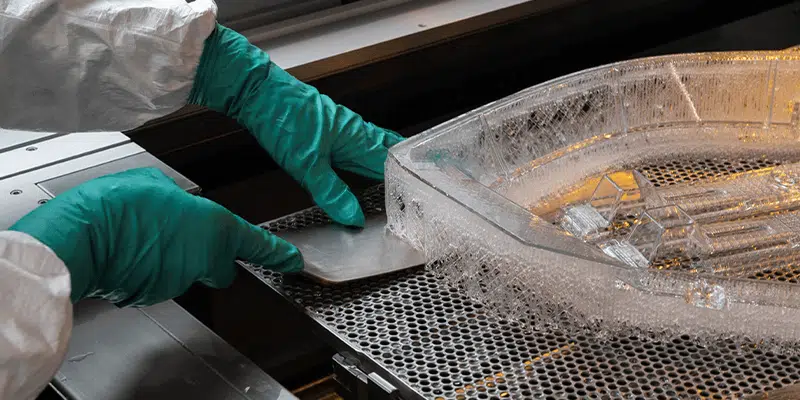

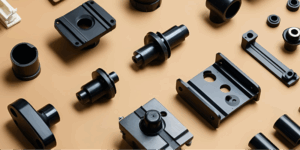

- Molded plastic components are commonly used in the automotive industry. They are used to make parts like dashboards, door panels, and other interior parts. These molded plastic components can be injection-molded or compression-molded from various plastics.

- Stainless steel is a material that has been around for hundreds of years. It is typically used for kitchen appliances, sinks, and other items where rusting is an issue. This type of steel is nonporous and corrosion-resistant.

- Tungsten carbide is used in many industries including mining, aerospace, and power tools. It is strong and durable and can withstand extremely high temperatures.

- Aluminum is a lightweight metal that is often used for beverage cans, food trays, and even car bodies. It is inexpensive and easy to work with, but it does have some drawbacks.

- Copper is a soft malleable metal that is widely used in electrical wiring due to its ability to easily conduct electricity. It is also useful for plumbing systems since it is generally able to carry water well.

SELECTING THE TYPE OF MATERIAL FOR A PROTOTYPE’S NEEDED MECHANICAL PROPERTIES OR USAGE

Manufacturers have many options when choosing a prototype material, but each option has its pros and cons. The structures of composite materials come as a solution to one or many circumstances in which the prototype or final product would be subjected to, for example, elevated temperatures.

In the selection of advanced materials, manufacturers may need to consider:

- Functional properties

- Fatigue strength

- Glass transition temperatures

- Material extrusion rates

- Tensile strengths

- Thermoset materials

WHAT MATERIALS ARE NEEDED IN THE PRODUCT DEVELOPMENT OF YOUR PROTOTYPE?

Choosing the right prototyping material can save time and money throughout the entire production cycle. To achieve their prototyping goals, manufacturers should consider their budget, the production volume, and the intended purpose of the prototype.

ARRK Asia is a team of experienced engineers, designers, and craftsmen who work with companies to create products from scratch. We know the chosen materials for prototyping affect the cost, the quality, and the features of the final product.

Our goal is to ensure our customers a result that will meet their specifications and expectations. If you require guidance and support during your prototyping process, do not hesitate to contact us. We will help you achieve your prototyping goals.