Silicone rubber molding has become a very important tool for the manufacturing sector. This technique is widely used to create durable components that require high precision and accuracy. It also allows the creation of complex shapes that would otherwise be impossible to achieve. But what are the advantages of using silicone rubber mold for Small-Lot Production?

At ARRK Asia, we have become a leading provider of silicone rubber molding services, allowing our partners to learn everything about how it works, how to speed the production process, and what challenges are to be faced during the manufacturing stage. Let’s discuss why we recommend silicone rubber mold for small lots.

Why Use Silicone Rubber Mold for Small-Lot Production?

There are many reasons why using silicone rubber mold is a good choice. First of all, it has good product quality and cost-efficiency performance. Secondly, it is flexible, strong, and durable. Thirdly, its surface is smooth, so it is easier to clean. In addition, it does not react easily with water, alcohol, oil, gas, or any chemical. Finally, it is easy to handle and safe to use. Therefore, it is suitable for Small-Lot Production due to its excellent properties such as:

- High strength

- Good elasticity

- Heat resistance

- Chemical stability

- Non-toxicity

- Easy processing

Advantages of Using Silicone Rubber Mold for Small-Lot production

- High Precision

The silicone rubber mold is suitable for Small-Lot Production due to its high precision. In addition, the silicone rubber mold is not only durable but also flexible. Therefore, it can be easily shaped according to different requirements. - Non-corrosive

Compared with metal molds, silicone rubber mold does not corrode. Moreover, the silicone rubber mold can be cleaned with water, alcohol, soap, or detergent. Thus, there is no need to wash the silicone rubber mold after use. - Low Cost

Since silicone rubber mold is cheap, it is suitable for Small-Lot Production. Besides, the silicone rubber mold requires little maintenance. If necessary, it can be easily replaced. - Easy to Clean

Due to its excellent anti-static properties, silicone rubber molds cannot attract dust particles. Therefore, when cleaning, the dirt is wiped off with a soft cloth. After cleaning, the silicone rubber mold should be dried naturally. - Durable

The silicone rubber mold can be reused for years without any damage. However, if the silicone rubber mold is damaged, it can be repaired easily. - Flexible

As mentioned above, the silicone rubber mold possesses flexibility. Therefore, it can meet various requirements. For example, it can be used for plastic products, glassware, ceramic ware, etc.

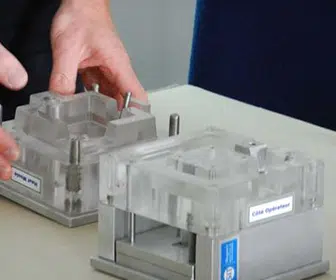

Providing Quality Products With Complex Specifications

It’s time to start using new technology in your business. ARRK has experience with silicone rubber mold production, offering a full range of services from design and engineering, molding and tooling, finishing, and inspection. Its extensive experience in the Rapid Prototyping and Injection Molding and Tooling in Asia allows us to provide turnkey solutions for new and existing customers.

Our company has over 70 years of combined experience providing End-to-end Prototyping in Asia, and we work closely with each customer to ensure successful product development and production. Contact us today!