BLOG CONTENT, NEWS AND PRESS RELEASES

Home » Blog Content, News and Press Releases

EXPANDING OUR EXPERTISE: ARRK’S DIGITALISATION & SOFTWARE SERVICES

For years, ARRK has been applying digital solutions to support product development and engineering processes across our global operations.

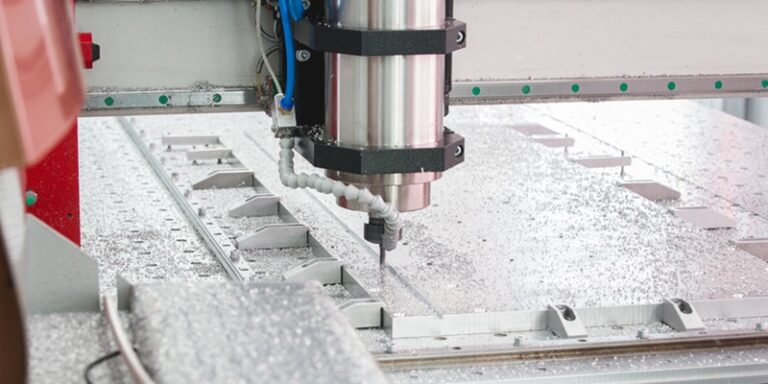

Read More »CNC Machining vs Injection Moulding: A Useful Guide

Want to learn the key differences between CNC machining and injection moulding? Read on to learn about the advantages, disadvantages, and similarities of each of the two method.

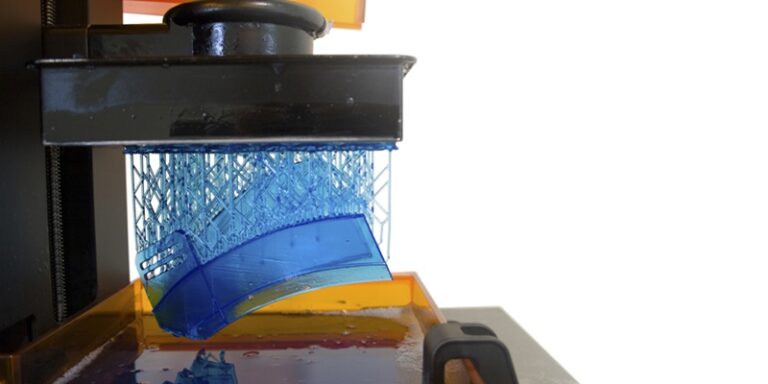

Read More »3D Printing vs Injection moulding: The Key Differences

Learn everything you need to know about 3D printing and injection moulding. In this article, we unveil the differences, similarities and the pros and cons of each method.

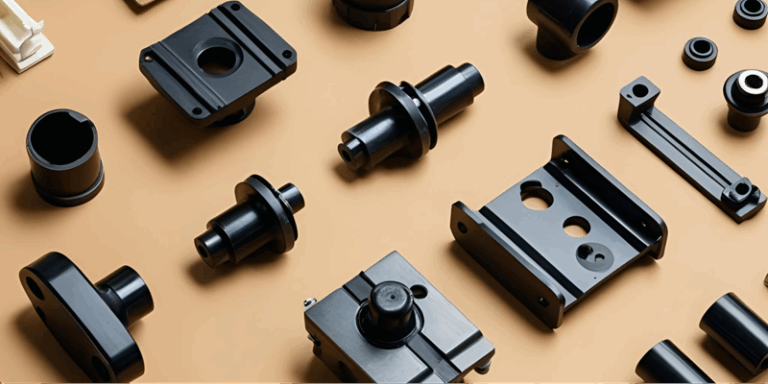

Read More »Understanding Overmoulding And Insert moulding

Curious about overmoulding and insert moulding? Read our article to find out everything you need to know about the two and how to choose the best option for your project!

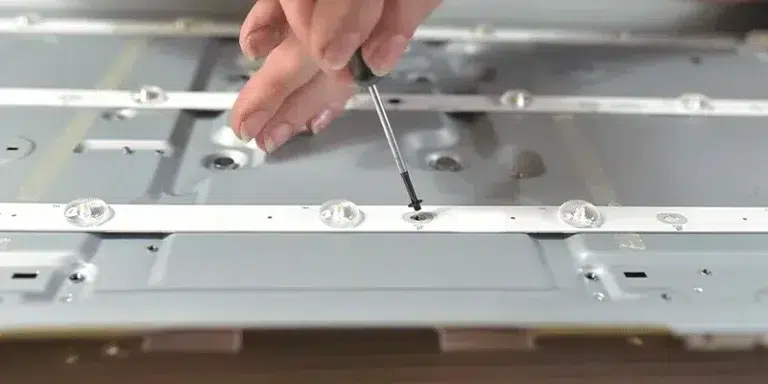

Read More »5 Ways to Tackle Low-Volume Manufacturing Challenges

Facing challenges with low-volume manufacturing? Discover 5 smart strategies to tackle high tooling costs, streamline supply chains, and overcome customization hurdles, ensuring high-quality results in small batches.

Read More »UNLOCKING THE POTENTIAL OF SHEET METAL FABRICATION

Count on ARRK Asia for your next metal sheet fabrication project! Whether you're crafting new parts for any industry, we have the expertise you need. Discover more here.

Read More »BEST PROTOTYPE MATERIALS FOR HIGH TEMPERATURES

Need reliable materials against heat and fires? ARRK Asia offers heat-resistant and fire-retardant solutions for your designs. Learn more about how we can help!

Read More »HOW CNC MACHINING ENHANCES PROTOTYPING?

What is the process of CNC machining? At ARRK Asia, we are experts in the benefits and challenges of this industrial method. Keep reading to learn more!

Read More »CRITICAL DESIGN ELEMENTS FOR EV CHARGING STATIONS

Get insights into EV charger development and how ARRK Asia delivers quality enclosures and casings for effective charging stations.

Read More »OPTIMISE PROTOTYPING: WHAT MAKES FOOD-GRADE MATERIALS SAFE?

How safe are food-grade materials? Dive into the details and find out how ARRK Asia's innovative approaches provide reliable solutions.

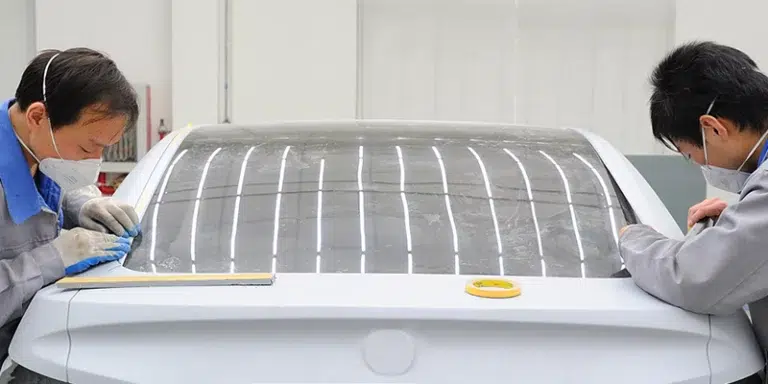

Read More »THE PERFECT BLEND: ADVANCING AUTOMOTIVE SAFETY AND STYLE

Discover how ARRK's expertise drives the integration of advanced safety systems and creating realistic models for new vehicle concepts.

Read More »DIE CASTING: RAPID AND QUALITY PRODUCTION

Discover the benefits of Die Casting in Malaysia with ARRK Asia. Our experienced team produces high-quality products with the most precision and efficiency.

Read More »THE IMPACT OF VACUUM CASTING FOR MEDICAL DEVICES

Explore why vacuum casting is a top choice in the medical device development and get expert tips from ARRK Asia.

Read More »WE ARE YOUR TRUSTED LOW-VOLUME AUTO MANUFACTURER PARTNER

Learn why ARRK Asia is the leading low-volume auto manufacturer you need. Produce high-quality and custom automotive parts and components with our team!

Read More »A GUIDE TO THE CONSUMER APPLIANCES INDUSTRY WITH ARRK ASIA

ARRK is your go-to manufacturer for the consumer appliances industry in Asia. Our experts provide insights and analysis to help make informed decisions.

Read More »EXPANDING OUR EXPERTISE: ARRK’S DIGITALISATION & SOFTWARE SERVICES

For years, ARRK has been applying digital solutions to support product development and engineering processes across our global operations.

Read More »CNC Machining vs Injection Moulding: A Useful Guide

Want to learn the key differences between CNC machining and injection moulding? Read on to learn about the advantages, disadvantages, and similarities of each of the two method.

Read More »3D Printing vs Injection moulding: The Key Differences

Learn everything you need to know about 3D printing and injection moulding. In this article, we unveil the differences, similarities and the pros and cons of each method.

Read More »Understanding Overmoulding And Insert moulding

Curious about overmoulding and insert moulding? Read our article to find out everything you need to know about the two and how to choose the best option for your project!

Read More »5 Ways to Tackle Low-Volume Manufacturing Challenges

Facing challenges with low-volume manufacturing? Discover 5 smart strategies to tackle high tooling costs, streamline supply chains, and overcome customization hurdles, ensuring high-quality results in small batches.

Read More »UNLOCKING THE POTENTIAL OF SHEET METAL FABRICATION

Count on ARRK Asia for your next metal sheet fabrication project! Whether you're crafting new parts for any industry, we have the expertise you need. Discover more here.

Read More »BEST PROTOTYPE MATERIALS FOR HIGH TEMPERATURES

Need reliable materials against heat and fires? ARRK Asia offers heat-resistant and fire-retardant solutions for your designs. Learn more about how we can help!

Read More »HOW CNC MACHINING ENHANCES PROTOTYPING?

What is the process of CNC machining? At ARRK Asia, we are experts in the benefits and challenges of this industrial method. Keep reading to learn more!

Read More »CRITICAL DESIGN ELEMENTS FOR EV CHARGING STATIONS

Get insights into EV charger development and how ARRK Asia delivers quality enclosures and casings for effective charging stations.

Read More »OPTIMISE PROTOTYPING: WHAT MAKES FOOD-GRADE MATERIALS SAFE?

How safe are food-grade materials? Dive into the details and find out how ARRK Asia's innovative approaches provide reliable solutions.

Read More »EXPANDING OUR EXPERTISE: ARRK’S DIGITALISATION & SOFTWARE SERVICES

For years, ARRK has been applying digital solutions to support product development and engineering processes across our global operations.

Read More »CNC Machining vs Injection Moulding: A Useful Guide

Want to learn the key differences between CNC machining and injection moulding? Read on to learn about the advantages, disadvantages, and similarities of each of the two method.

Read More »3D Printing vs Injection moulding: The Key Differences

Learn everything you need to know about 3D printing and injection moulding. In this article, we unveil the differences, similarities and the pros and cons of each method.

Read More »Understanding Overmoulding And Insert moulding

Curious about overmoulding and insert moulding? Read our article to find out everything you need to know about the two and how to choose the best option for your project!

Read More »5 Ways to Tackle Low-Volume Manufacturing Challenges

Facing challenges with low-volume manufacturing? Discover 5 smart strategies to tackle high tooling costs, streamline supply chains, and overcome customization hurdles, ensuring high-quality results in small batches.

Read More »