Handling product development and choosing a low-volume plastic manufacturing process will give several options. But how should one decide?

A good volume production service team would be able to offer the best advice on selecting from the different types of plastic manufacturing processes. So, now it would be crucial to select a method of creating low-volume plastic parts, from product design to the finished product.

There are several manufacturing processes available in the market for any volume run.

By knowing the advantages of each low-volume manufacturing in Asia process available, it can give a better understanding of the end results possible.

4 THINGS TO CONSIDER WHEN SELECTING THE RIGHT PLASTIC MANUFACTURER FOR YOUR PROJECT

- Advanced manufacturing facilities

- Manufacturing expertise

- Product development experience

- Design for manufacturing support

Once you have this covered, selecting the right type of plastic materials is something to be communicated properly. The end-user, the manufacturing process, and other specifications would have the final say on which plastic compound can or should be used.

HOW TO MANUFACTURE YOUR PLASTIC PRODUCT

Obtaining the desired plastic product with ARRK Asia will provide a wide range of options to design for manufacturing with Injection molding in Malaysia, tooling in Singapore, or die casting in Malaysia processes. Each process must adhere to the specifications of your project to be assured of the desired end result. We are capable of providing thin-wall injection molding, double-shot molding, over-molding, insert molding, and transparent and high-polished molding.

In other companies, you might find several roadblocks, such as design data modification without proper communication, making the product unusable, or forcing you to revise and delay plans due to unexpected outcomes. Besides not having the product right, components could take up longer than expected to complete, and if that is not bad enough, they have limited materials available.

MAKE A DIFFERENCE WITH OUR LOW VOLUME PLASTIC MANUFACTURING

- No design restrictions

- Results in three weeks

- Wide range of available materials

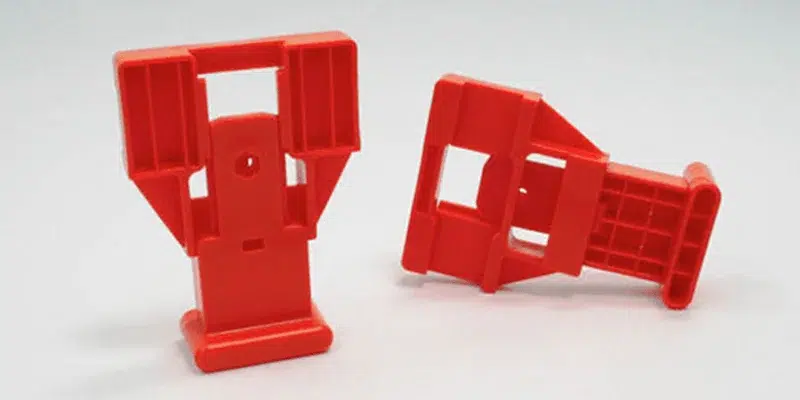

INJECTION MOLDING

The most advanced and efficient way of mass-producing plastic parts is through injection moulding. This process involves injecting plastic materials molten by heat into a steel mould, and then cooling and solidifying them. Products of complex shapes and various sizes can be produced with the following advantages:

- Creating custom objects

- Increase productivity

TOOLING

As experienced providers for the industry, we offer custom tooling services that include fixtures, jigs, cutting tools and patterns, assembly jigs, gauges, molds, and dies, to mention a few.

- Quality manufacturing components

- Quality manufacturing machines

DIE CASTING

Die casting is a process that inserts molten metal under high pressure into reusable molds called dies to produce high-quality components for multiple purposes. ARRK Asia can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

- Sharply defined parts

- Suitable present dimensions

- Good results in any finishing, from smooth to textured

GUIDANCE FROM START TO FINISH UNTIL OBTAINING SUCCESSFUL RESULTS

The right method for a given low-volume order will depend on factors such as part application, material, and timeline. The entire production process is supported by our expert designers and engineers. By partnering with full-service manufacturing like ARRK Asia, it could be the best course of action taken by your company.

To give your customers the best possible service when using your products, count on ARRK in Asia to reach your company’s production goals.

Get in contact with our team, submit your quote today, and we’ll reply with your estimate as soon as possible.