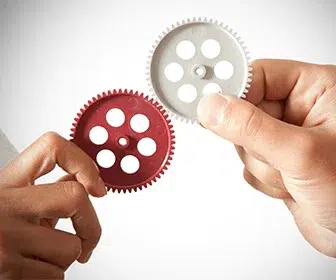

Depending on the process used, low-volume manufacturing in Malaysia is usually limited to 5,000 pieces or fewer. This option allows for a more controlled investment in tooling and materials while allowing quick access to markets, rapid response to shorter product life cycles, and as a bridge between initial prototypes and high volume production.

Those three reasons are what bring companies into the low-volume production world. Setting goals in the company needs to be a tangible and solution-based guideline, if the company doesn’t already handle such manufacturing, selecting suitable and reliable 3rd party vendors can be challenging.

Respond quickly to rapidly changing market conditions

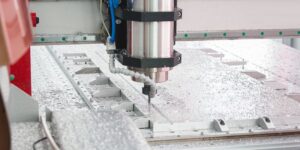

While traditional manufacturing methods such as plastic injection molding may be the best choice when your project requires a higher volume of parts, low volume production has seen a surge in popularity in recent years.

The reason is that it allows industries to spend less time and money on tooling and materials while getting to market faster. Also, companies can respond to design changes quickly due to market changes in requirements or demand.

Benefits of Low Volume Manufacturing include:

- Quicker time-to-market with less risk due to lower capital requirements

- Lower cost per unit produced

- More control over quality through tighter tolerances

- Ability to produce small quantities at higher volumes than larger ones

- Lowest possible lead times from order placement to delivery

- No need for large inventories of raw materials

Due to the specialization of such pieces, it can also be the best solution for a complex geometric fill part or end product, allowing attention to detail and not having high volume production manufacturing as an option. In the end, what is best for the company is what keeps its customers coming back for more. Keep your customers happy with the right manufacturer partner in Thailand.

Choosing what is best for the company’s project

Even if a decision has been made already, having an experienced team that puts the needs of the project as a priority is just as crucial. Working in the prototyping process with the right and dedicated teams that handle innovative products is crucial in maintaining the trust and loyalty of customers.

It’s important for companies to be up-to-date with manufacturing processes. Each device has to meet public safety guidelines or international certifications. Here in ARRK in Asia, we are capable and aware of the needs of your products for a successful manufacturing run.

Get in contact with the team to get a personalized quote.